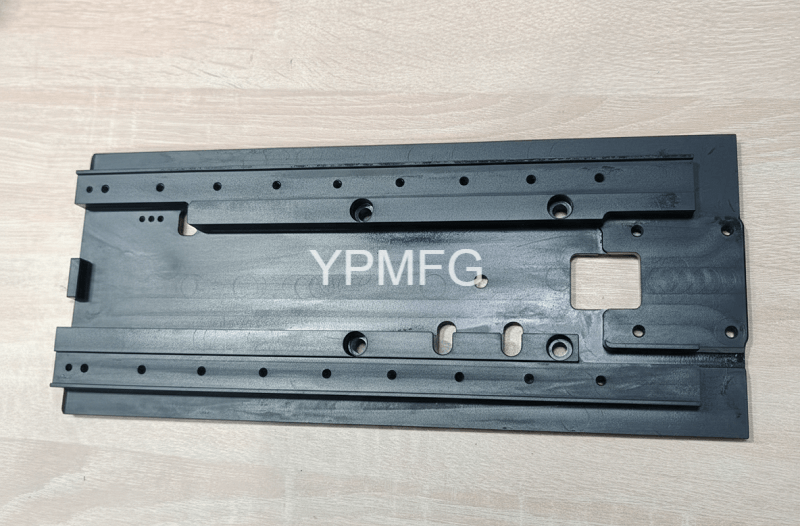

This project involved the custom CNC machining of precision mechanical components used in industrial machinery and equipment assemblies. The customer required stable dimensional accuracy, reliable assembly fit, and durable surface protection for parts operating in a mechanical environment with frequent installation and disassembly.

Based on the provided drawings and technical notes, the parts were manufactured from mild steel and finished with bead blasting followed by black zinc plating, ensuring both functional performance and corrosion resistance.

1. Part Overview

Part Type: Machined mechanical equipment components

Manufacturing Process: CNC machining

Material: Mild steel (carbon steel)

Surface Finish: Bead blasting + black zinc plating (15 μm)

The project includes multiple CNC-machined parts with distinct structural characteristics:

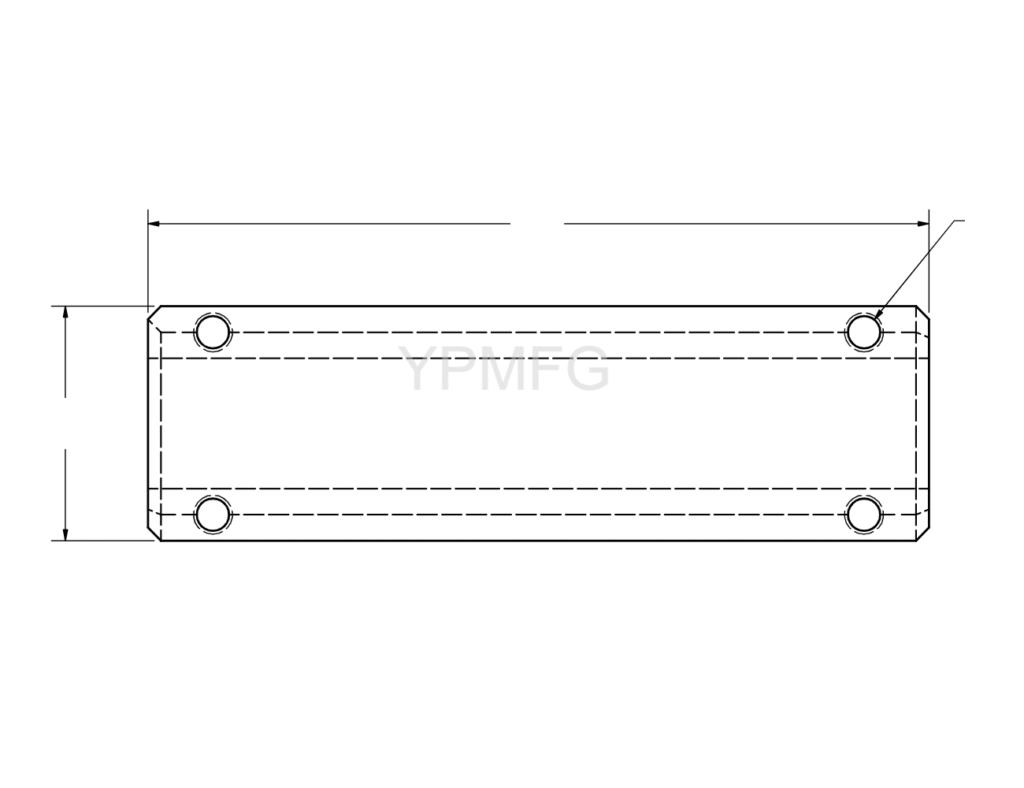

Plate-type component

- Long, rectangular geometry with multiple precision-drilled holes

- Countersunk and through holes for fastener installation

- Machined slots and cut-outs requiring consistent positional accuracy

- Flatness and edge quality critical for proper mounting

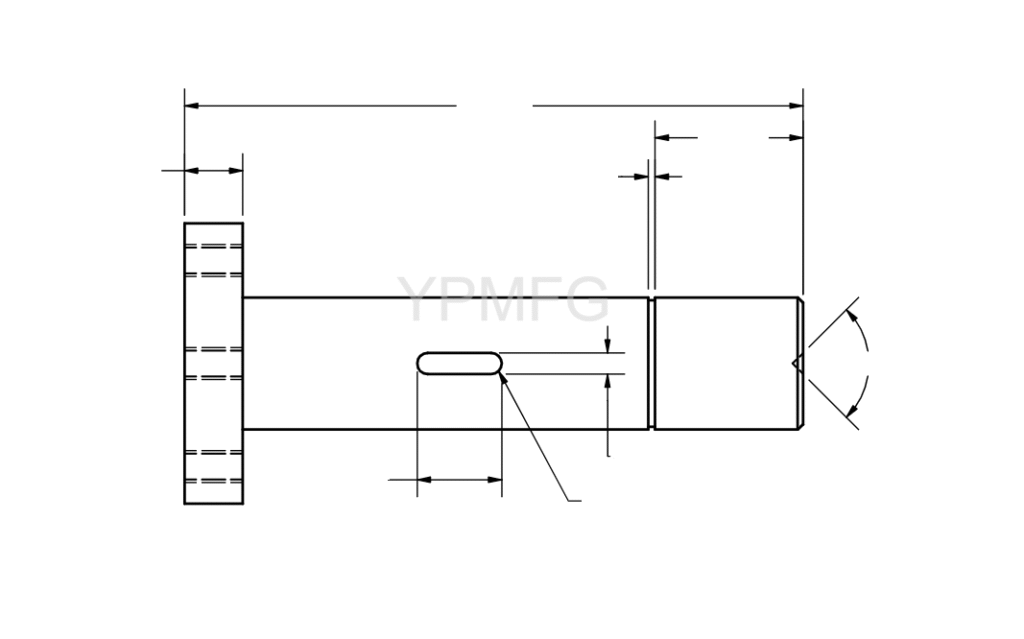

Shaft-type component

- Cylindrical geometry with stepped diameters

- Threaded holes (metric internal threads) on the end face

- High concentricity between shaft and flange surfaces

- Smooth surface finish for assembly alignment

All dimensions are specified in metric units, with a general tolerance of ±0.15 mm, and critical features controlled more tightly according to the drawings.

2. Machining Challenges

Several technical challenges were identified during production:

1. Multiple Hole Alignment

The plate component includes a series of closely spaced holes and slots, requiring precise positioning to ensure assembly compatibility.

2. Dimensional Consistency on Long Parts

Maintaining straightness and dimensional stability on elongated plate geometries can be challenging due to internal stress release during machining.

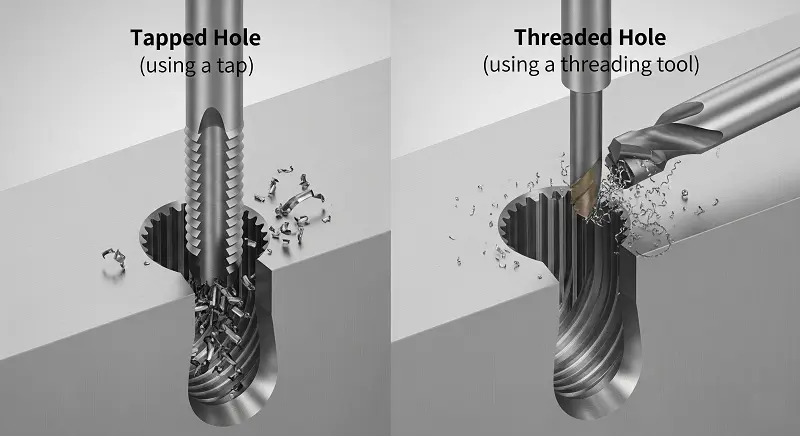

Thread Quality in Carbon Steel

Internal threads (e.g. M3, M6) require controlled tapping parameters to avoid burrs, deformation, or poor thread engagement.

3. Surface Finish & Coating Compatibility

The final surface treatment needed to maintain dimensional integrity while providing corrosion protection without clogging threads or key features.

3. CNC Machining Solution

To address these challenges, a structured CNC machining solution was applied:

Machining Process

- CNC milling for contouring, slotting, drilling, and countersinking of plate components

- CNC turning for shaft components, including stepped diameters and face machining

- Precision tapping for internal metric threads

Equipment & Tooling

- High-rigidity CNC machining centers for flatness and positional accuracy

- Sharp carbide cutting tools optimized for mild steel

- Dedicated tapping tools to ensure thread quality and repeatability

Quality Control

- Dimensional inspection based on engineering drawings

- Thread depth and fit verification

- Visual and tactile inspection after bead blasting

- Coating thickness control during black zinc plating (15 μm)

All sharp edges were deburred as specified, ensuring safe handling and improved assembly performance.

4. Final Results & Customer Benefits

The finished CNC machined parts met all drawing requirements and surface treatment specifications:

- Accurate dimensions and consistent hole positioning

- Clean threads with reliable assembly fit

- Uniform black zinc plated surface with enhanced corrosion resistance

- Improved durability and professional appearance for industrial use

By combining precision CNC machining with a controlled surface finishing process, the customer received high-quality custom machined parts ready for direct installation, reducing assembly issues and long-term maintenance risks.