1. Project Background

As the tattoo equipment industry continues to evolve toward higher precision and durability, manufacturers are placing greater emphasis on the quality and consistency of critical mechanical components.

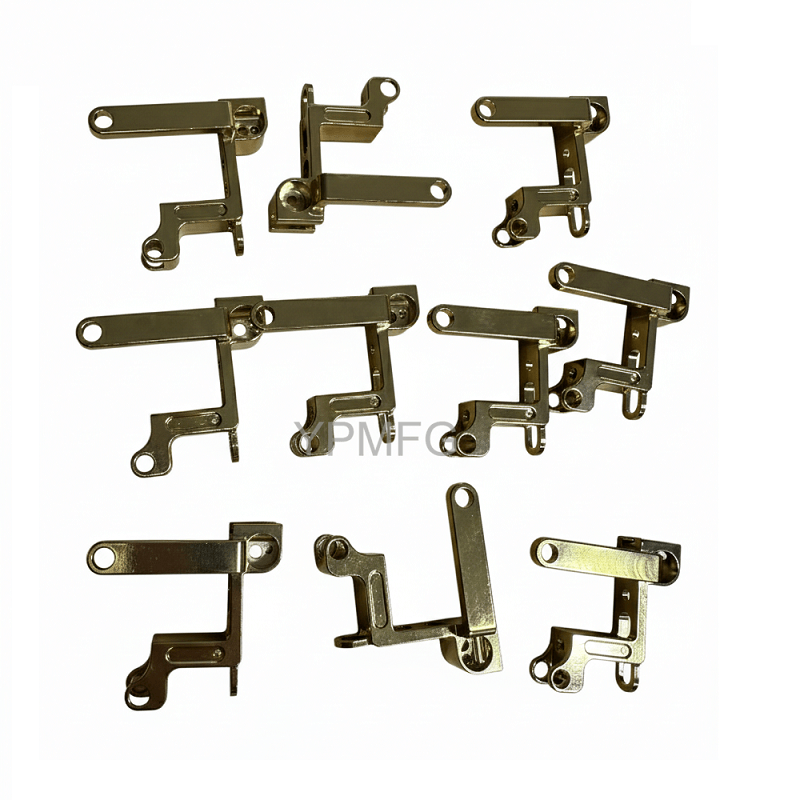

For this project, the customer is a professional tattoo machine manufacturer seeking a reliable CNC machining supplier to produce carbon steel tattoo machine components used in the core mechanical assembly. The primary goals were structural strength, dimensional consistency, and stable performance during long-term operation.

Carbon steel was selected to meet the application’s requirements for wear resistance and mechanical reliability while maintaining cost efficiency for batch production.

2. Part Overview

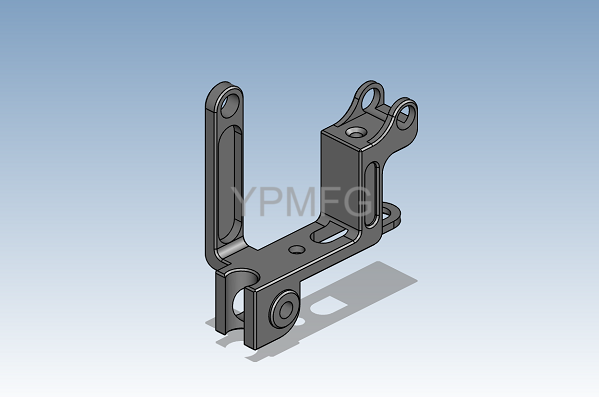

Part Name: Tattoo Machine Components

Industry: Tattoo Equipment / Precision Mechanical Assemblies

Material: Carbon Steel

Surface Treatment: Polishing with protective surface coating (for corrosion resistance and appearance)

These components serve as structural and motion-related parts inside the tattoo machine, responsible for alignment, linkage, and mechanical stability. Their performance directly affects the smooth operation and service life of the final equipment.

Key Geometric Features

- Multi-level stepped profiles with varying thicknesses

- Combination of slender arms and reinforced load-bearing sections

- Multiple precision holes for pins, screws, and pivot connections

- Complex contours, internal radii, and machined slots

- Compact size with dense machining features

Although the parts appear relatively small, their geometry demands precise machining and strict process control.

3. Machining Challenges

1. Carbon Steel Machinability

Compared to non-ferrous materials, carbon steel generates higher cutting forces and accelerates tool wear. Stable machining parameters and proper tooling selection were essential, especially for thin sections and detailed features.

2. Complex Geometry with Tight Feature Relationships

The parts include multiple functional surfaces and hole locations that must maintain accurate positional relationships to ensure smooth assembly and reliable motion.

3. Batch Consistency Requirements

Tattoo machine components are typically produced and assembled in batches. Dimensional variation between parts could lead to assembly issues or inconsistent machine performance.

4. Surface Quality and Corrosion Protection

As carbon steel is susceptible to corrosion, both surface finish quality and post-machining treatment were critical to meet functional and aesthetic expectations.

4. Machining Solution

1. Process Strategy

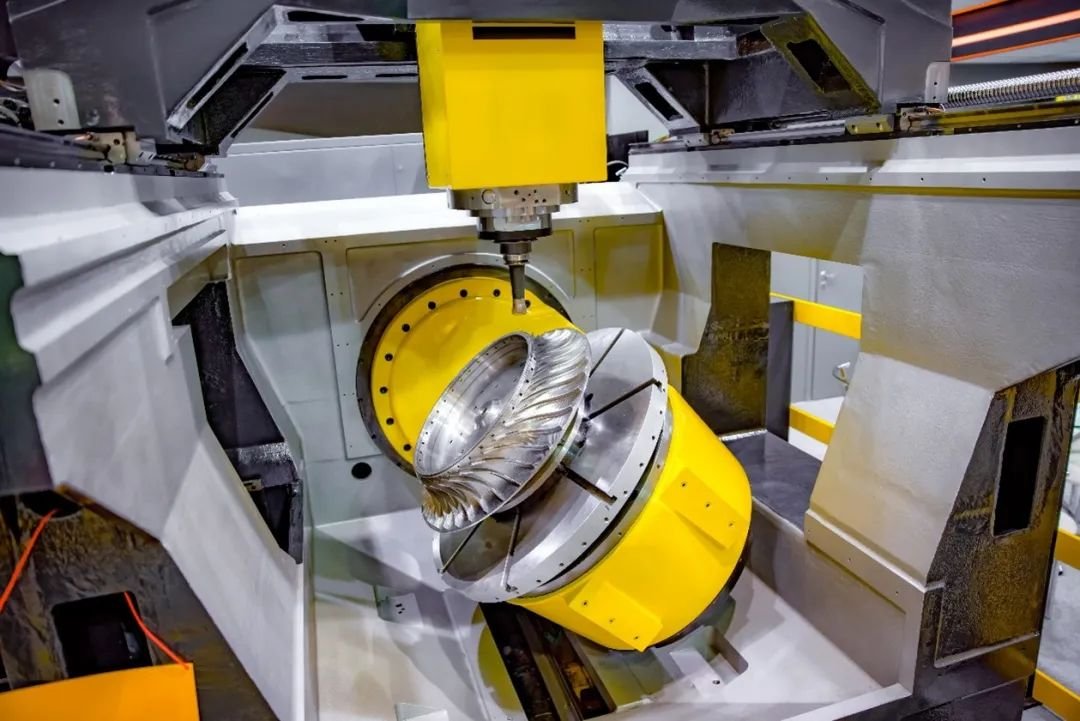

A staged CNC machining approach was implemented to balance efficiency, accuracy, and surface quality:

- Rough Machining

Efficient material removal while controlling cutting forces to minimize deformation. - Semi-Finishing

Establishment of stable reference surfaces and machining of critical planes and hole features. - Finish Machining

Final contouring, slotting, and hole finishing to achieve dimensional accuracy and clean surface quality.

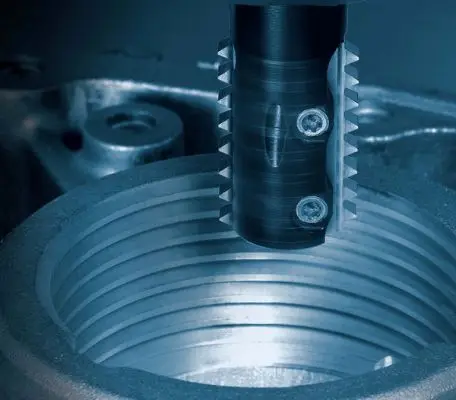

2. Equipment & Tooling

- High-rigidity CNC machining centers

- Custom-designed fixtures to support asymmetric geometry and thin features

- Coated carbide end mills and precision drills optimized for carbon steel machining

3. Quality Control

- In-process inspection of critical dimensions

- Deburring and edge-breaking to ensure safe handling and smooth assembly

- Sample assembly verification to confirm functional fit within the tattoo machine

5. Final Results & Customer Benefits

- Stable dimensional accuracy across production batches

- High structural strength suitable for long-term mechanical operation

- Clean, consistent surface finish supporting subsequent coating or plating

- Reduced assembly issues and improved production efficiency

The customer successfully integrated the machined components into their tattoo machine assemblies, meeting both performance and quality expectations.

6. Conclusion

This project highlights the importance of precision CNC machining for complex carbon steel components used in compact mechanical assemblies. Through careful process planning, robust fixturing, and strict quality control, we delivered reliable, repeatable results suitable for ongoing production.

If you are looking for a CNC machining partner with experience in carbon steel precision parts for mechanical equipment, our team is ready to support your next project.