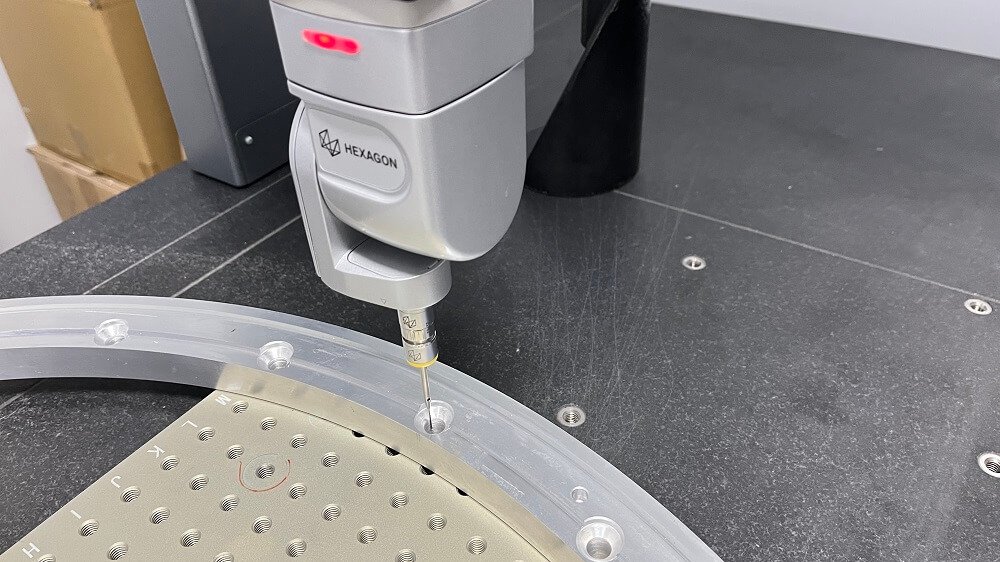

In the fields of CNC Machining and metal fabrication, manufacturing high-precision parts is only the initial step. Selecting the appropriate Surface Finishing is critical to ensure the long-term stability and integrity of the components throughout their service life.

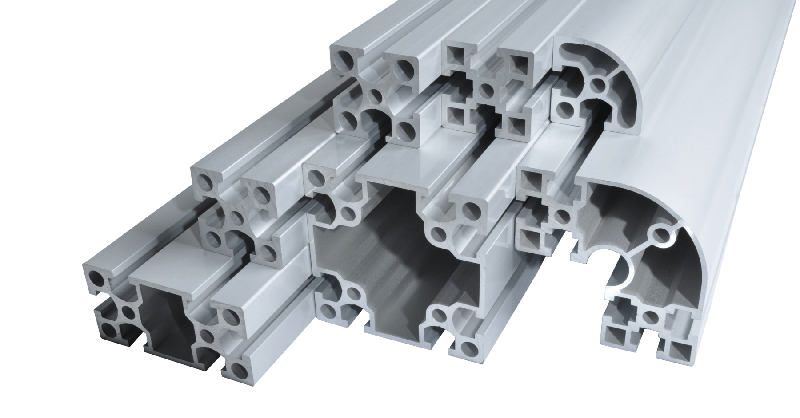

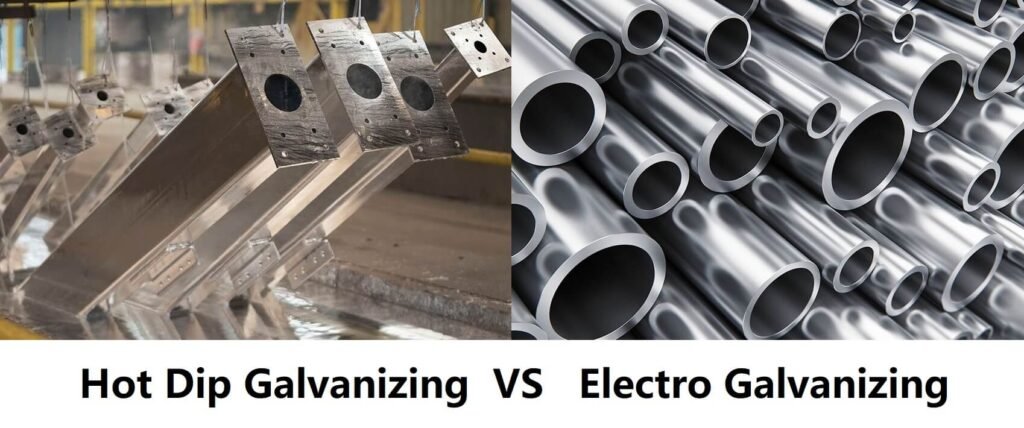

Galvanizing (zinc coating), as one of the most established corrosion protection processes, is widely used for steel structures. However, Hot Dip Galvanizing (HDG) and Electro-Galvanizing, though differing by only one word vary significantly in their process principles, anti-corrosion performance, and application scenarios. This article provides an in-depth analysis of both techniques from a materials science and engineering application perspective.

Table of Contents

I. What is Hot-Dip Coating?

1. Definition and Basic Characteristics

Hot-Dip Coating, or simply Hot Dip, is a method of applying a coating by immersing the base metal material into a bath of other liquid metals or alloys with a relatively low melting point.

The fundamental characteristic of hot dip coating on steel is the formation of an alloy layer (intermetallic layer) between the steel substrate and the pure zinc coating. When the steel component is withdrawn from the molten zinc bath, a layer of molten zinc adheres to this alloy layer. Upon cooling and solidification, this forms the final, pure zinc coating.

2. Substrate and Coating Materials for Hot-Dip Coating

Steel is the primary substrate material for hot dip processes. Therefore, the coating metal must have a significantly lower melting point than steel.

It is generally accepted that steel suitable for hot dip coating is low-silicon, rimmed steel. For instance, the US Metal Handbook specifies that the silicon content (wSi) should be less than 0.05%. Some literature indicates that Grade B of Q235 steel is most suitable for hot dip coating, as it results in a compact, continuous, and uniform intermetallic compound structure after treatment.

The widespread use of continuous casting technology has introduced new challenges to hot dip coating, as these modern steel grades often have a silicon content greater than 0.05%. Consequently, hot dip coating can be challenging for steel workpieces that are not low-carbon or have too low or too high a silicon content. However, these challenges can often be overcome through alternative process methods.

Coating Materials:

Common coating metals include Zinc (melting point 419.5°C), Aluminum (melting point 658.7°C), Tin (melting point 231.9°C), and Lead (melting point 327.4°C). Compared to other metals, zinc is a relatively inexpensive and easily applied metal. It is categorized as a low-cost, anti-corrosion layer and is widely used to protect steel components, especially against atmospheric corrosion, in addition to decorative purposes.

3. Plating Technology

The following techniques belong to Electro-Galvanizing (or Cold Galvanizing) processes:

- Coating Techniques: The main methods include Rack Plating (for larger parts), Barrel Plating (suitable for small parts), Automatic Plating, and Continuous Plating (suitable for wires and strips).

- Classification by Plating Solution: Currently, electro-galvanizing solutions can be categorized into four main types: Cyanide Zinc Plating, Zincate Zinc Plating, Chloride Zinc Plating, and Sulfate Zinc Plating.

II. What is Hot Dip Galvanizing (HDG)?

1. Definition of Hot Dip Galvanizing

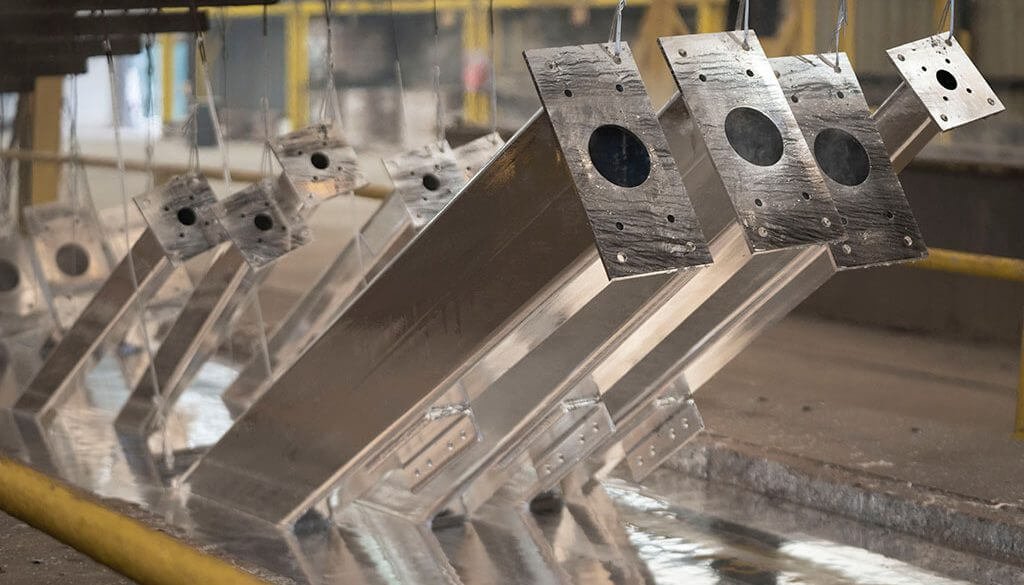

Hot Dip Galvanizing (HDG), also known as galvanizing, is a method of obtaining a metallic overlay by immersing steel components in a bath of molten zinc.

2. The Formation Process of the HDG Layer

This refers to the process where a zinc-iron alloy is formed between the iron substrate and the outermost layer of pure zinc. The formation of this iron-zinc alloy layer during the hot dip process ensures a strong metallurgical bond between the steel and the pure zinc layer. The process can be summarized as follows:

- When the iron workpiece is immersed in the molten zinc, an initial solid solution of zinc and alpha-iron (BCC) forms at the interface.

- Once the zinc in the solid solution reaches saturation, zinc and iron atoms diffuse into each other. Zinc atoms migrating into the iron substrate lattice gradually form alloys with the iron.

- Iron diffusing into the molten zinc forms the intermetallic compound FeZn13, which sinks to the bottom of the galvanizing pot, known as zinc dross.

- When the steel component is withdrawn from the molten zinc bath, a surface layer of pure zinc (hexagonal crystal structure, iron content no greater than 0.003% adheres and solidifies.

3. The Entire Hot Dip Galvanizing Process

Taking the “Dry Method” HDG as an example, steel pipes coated with a fluxing agent (zinc and ammonium chloride) are preheated in a drying oven to a temperature of 150°C to 200°C, before being immersed into a zinc bath maintained at 440°C to 450°C.

- Initially, the steel instantaneously absorbs a large amount of heat, causing the zinc on its surface to suddenly cool and solidify, forming a temporary solid shell.

- As heat transfer continues, this shell quickly melts.

- When the temperature of the steel surface and the zinc bath equalize, the molten zinc begins to interact with the steel, forming the iron-zinc alloy layer over time.

- The pure zinc layer connects to the outside of the alloy layer, which crystallizes upon cooling, connecting the inner alloy layers to the steel substrate.

The entire process is complex, involving physical changes, chemical reactions, wetting, diffusion, and dissolution between the solid steel and molten zinc. The rate of this process is significantly influenced by the steel’s chemical composition, the temperature of the zinc bath, and the duration and depth of immersion.

The actual process of zinc coating on the steel surface proceeds in these steps:

Solid Iron Dissolves→ Iron combines with Zinc to form Iron-Zinc Alloy Compounds, creating the Iron-Zinc Alloy Layer → The Pure Zinc Layer connects to the outside of the alloy layer, crystallizing upon cooling, with the Steel Substrate connecting to the inner side of the zinc layers.

Therefore, the HDG process is primarily a diffusion-driven process that forms the galvanized layer.

4. The Protective Role of the Zinc Coating on Steel

1) Key States of Galvanized Steel Components:

- Intact Surface: When the surface is undamaged, only the zinc corrodes. Since the corrosion products of zinc offer good self-protection, the corrosion rate is very slow, giving the part a lifespan 15 to 30 times longer than ungalvanized steel.

- The metallurgical bond between the HDG layer and the steel substrate is unique to hot dipping, providing excellent resistance to mechanical damage during processing, storage, transport, and installation.

- The HDG layer completely covers all parts of the steel component, including internal surfaces, external surfaces, corners, and narrow crevices.

- Locally Damaged Surface (Sacrificial Protection): When the coating is locally damaged (e.g., by scratching), exposing the steel substrate, the characteristic sacrificial protection property of galvanized steel drastically slows the corrosion rate.

- In a moist environment, the zinc coating and the iron substrate form a galvanic cell. Since the standard electrode potential of zinc is -1.05 V (lower than iron’s -0.036 V), zinc acts as the anode and is preferentially oxidized, thereby providing cathodic protection to the iron (the cathode). This process is known as Sacrificial Corrosion Protection.

- Adhesion is Key: Generally, corrosion does not involve uniform erosion of the entire zinc layer but starts where the bond between the coating and the substrate is weak. From this perspective, the adhesion (especially overall adhesion) of the zinc coating is more critical than its thickness. Poor local adhesion, even with a thick coating, will initiate rusting at the weak point.

2) Threefold Anti-Corrosion Protection Provided by HDG:

- Barrier Layer Protection: The HDG layer is a hard, metallurgically bonded barrier that completely covers the steel surface, isolating the steel from the corrosive environment.

- Corrosion Product Layer Protection: Corrosion products formed on the HDG surface expand in volume, plugging small gaps caused by the selective dissolution of the coating. This barrier slows down further corrosion in the environmental medium.

- Electrochemical Protection (Sacrificial Protection): For any small areas exposed by accidental damage (like dents or scratches), the HDG layer acts as a sacrificial anode because zinc is more electronegative than iron, providing cathodic protection to the underlying steel.

5. How Good is Hot Dip Galvanizing?

1) Advantages of the HDG Process

Compared to other metal anti-corrosion methods, the HDG process offers unparalleled advantages in terms of electrochemical protectiveness, coating density, durability, maintenance-free longevity, strong bond with the substrate, cost-effectiveness, adaptability to various steel shapes/sizes, and high production efficiency.

HDG steel retains excellent formability, weldability, paintability, and ductility, driving the HDG technology toward large-scale, low-cost development.

2) Coating Thickness and Lifespan

The lifespan of the zinc coating is primarily determined by its thickness. The thickness can be easily and accurately measured using a magnetic thickness gauge.

Atmospheric exposure tests indicate that an 86 µm thick HDG coating has a service life of approximately 13 years in heavy industrial areas, 50 years in marine environments, 104 years in rural areas, and 30 years in urban zones.

Generally, a zinc mass of 600 g/m2 provides a maintenance-free service life of 20 to 50 years.

III. What is Electro-Galvanizing? (Cold Galvanizing)

Electro-Galvanizing, commonly known as “Cold Galvanizing” or “Water Galvanizing,” is an electrochemical process. The zinc ingot serves as the anode, releasing electrons and dissolving into the electrolyte solution as zinc ions. The steel material acts as the cathode, where the zinc ions gain electrons and are reduced back into zinc atoms, depositing onto the steel surface. This process forms a uniform, dense, and well-bonded metallic or alloy deposited layer.

IV. Key Differences Between Hot Dip Galvanizing (HDG) and Electro-Galvanizing

| Feature | Hot Dip Galvanizing (HDG) | Electro-Galvanizing (Cold/Water Plating) |

| 1. Coating Thickness | Thick: Typically 40 µm or more, often over 100µm (10 to 20 times thicker than electro-galvanizing). | Thin: Approximately 3 µm to 15 µm. |

| 2. Zinc Mass | High: Minimum double-sided mass typically 50 to 60 g/m2, max up to 600 g/m2. | Low: Minimum 15 g/m2, maximum typically 100 g/m2 (due to production line speed limitations). |

| 3. Layer Structure | Metallurgical Bond: Features a slightly brittle iron-zinc alloy layer between the pure zinc and the steel. Forms “spangle” crystals. The coating is uniform and non-porous. | Physical Adhesion: Zinc atoms are only deposited on the surface (physical bond). Contains many micropores, making it susceptible to pitting corrosion. |

| 4. Corrosion Resistance | Excellent: Superior protection due to thickness and sacrificial action. Life expectancy 20-50+ years. | Poor to Moderate: Thinner layer, less sacrificial zinc available. Life expectancy 3-5 years (untreated). |

| 5. Substrate Treatment | Often uses cold-hardened sheet as raw material, with continuous annealing on the line, affecting mechanical properties slightly. Lower cost. | Uses cold-rolled sheet as raw material, generally preserving the original mechanical properties. Higher cost due to complex process flow. |

| 6. Appearance | Rougher, brighter surface, may exhibit spangle (zinc flower pattern). | Smooth, dull/grey surface. |

| 7. Coverage | Excellent wetting: Covers all surfaces, including inner walls/cavities of tubes/pipes. | Only coats the surface exposed to the electrolyte (e.g., outer wall of a pipe). |

Summary:

- HDG offers excellent coverage, a dense coating, strong adhesion (metallurgical bond), and a long service life. Its resistance to atmospheric corrosion is superior to electro-galvanizing.

- Electro-Galvanized steel offers good workability but has a thinner coating and inferior corrosion resistance. It is often limited to outer surface plating.

Ⅴ. Engineer Selection Recommendations

As experienced manufacturing experts, we recommend choosing the surface finishing based on the part’s application environment and tolerance requirements:

| Selection Consideration | Recommended Process | Rationale |

| Outdoor Structural Components / Harsh Environments | Hot Dip Galvanizing (HDG) | Corrosion protection is the #1 priority. Sacrifice some appearance and precision for a 30+ year lifespan. |

| Precision CNC Parts / Fasteners | Electro-Galvanizing (Zinc Plating) | Must guarantee ± 0.01 mm level tolerances and require a fine aesthetic finish. |

| Slender Tubes / Internal Cavity Protection | Hot Dip Galvanizing | Only the wetting ability of HDG can ensure complete zinc coverage on the inner walls. |

| Requires Subsequent Painting (Topcoat) | Electro-Galvanizing / Phosphating | The electroplated surface is flat and provides an excellent base coat for painting. HDG requires prior sweep blasting. |

Ⅵ. Conclusion

Whether choosing the superior weather resistance of Hot Dip Galvanizing or the precision aesthetics of Electro-Galvanizing, understanding the principles behind the process is key to success.

At YPMFG, we not only provide high-quality Custom CNC Machining services but also have an experienced engineering team to review your Design for Manufacturing (DFM). We will recommend the most suitable surface treatment based on your application environment, ensuring your parts achieve the optimal balance between performance and cost.

Questions about surface finishing standards? Contact our engineering team immediately for professional advice on coating thickness and quotation.