In the procurement and machining of mechanical parts, the quality of the components directly determines the performance, reliability, and service life of the final product. For customers, understanding the key inspection points of machined parts not only ensures that received parts meet design requirements but also effectively reduces rework, production delays, and cost risks. This article provides a comprehensive guide to inspecting CNC machined parts from four key aspects: appearance, dimensions, tolerances, materials, and functionality, along with practical inspection processes and precautions.

Ⅰ. Appearance Inspection

Appearance is the most direct reflection of the quality of machined parts and serves as an important reference for evaluating machining skill and process quality. A good appearance not only reflects precision and craftsmanship but also directly affects assembly ease and the overall aesthetic of the product. When inspecting parts, customers should focus on the following aspects:

1. Surface Quality

- Surfaces should be smooth and even, free from scratches, burrs, flash, pores, cracks, or other defects. Machining patterns should be uniform, and cutting marks should not be too deep or irregular.

- Surface roughness (Ra value): Surface roughness is a key indicator of machining quality, directly affecting friction, wear resistance, and assembly fit. For example, high-precision mating parts with inadequate surface roughness may result in assembly difficulties or unstable operation.

- Local defects: For wear-prone or load-bearing areas, carefully check for micro-cracks or pores, as these defects may expand during use and reduce part lifespan.

2. Machining Marks

- Check the depth and uniformity of tool marks. Excessive or uneven marks can lead to stress concentration, increasing the risk of cracking or deformation.

- Surface treatment inspection: For parts with anodizing, coating, or plating, ensure the coating is uniform, without peeling, bubbles, or color variations.

- Edges and transition surfaces: Chamfers, hole edges, and transitions should be smooth, free of burrs or sharp corners to prevent interference or damage during assembly or use.

3. Color and Markings

- Color consistency: Coated or anodized parts should have a uniform color with no visible variations, ensuring a consistent overall appearance.

- Clear markings: Part numbers, engravings, or labels should be legible and correctly positioned for traceability and batch management.

- Functional markings: If parts have functional indicators (e.g., axis orientation, rotation direction, assembly position), they must be correct to avoid assembly errors.

Ⅱ. Dimensional and Tolerance Inspection

Dimensional accuracy is one of the most critical indicators for machined parts, directly determining whether a part can be properly assembled, operate smoothly, and maintain long-term reliability. During acceptance, customers should focus on the following aspects:

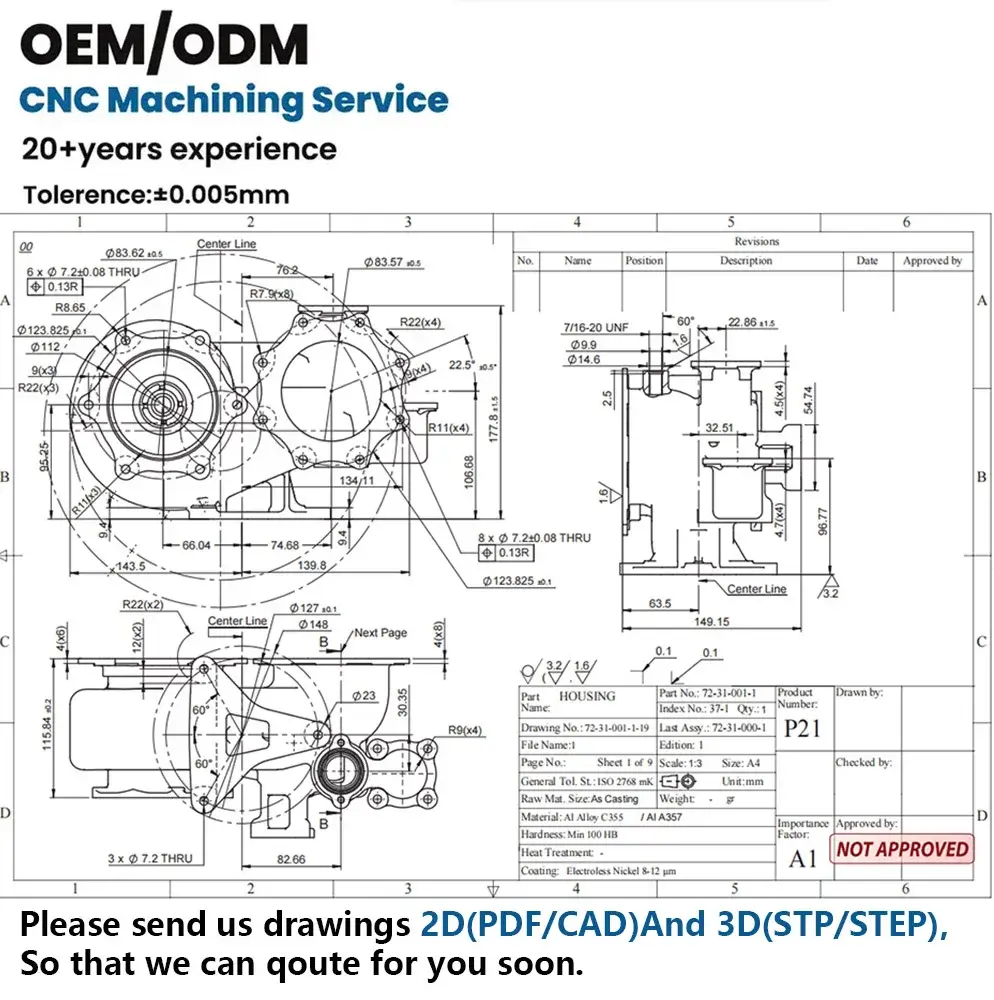

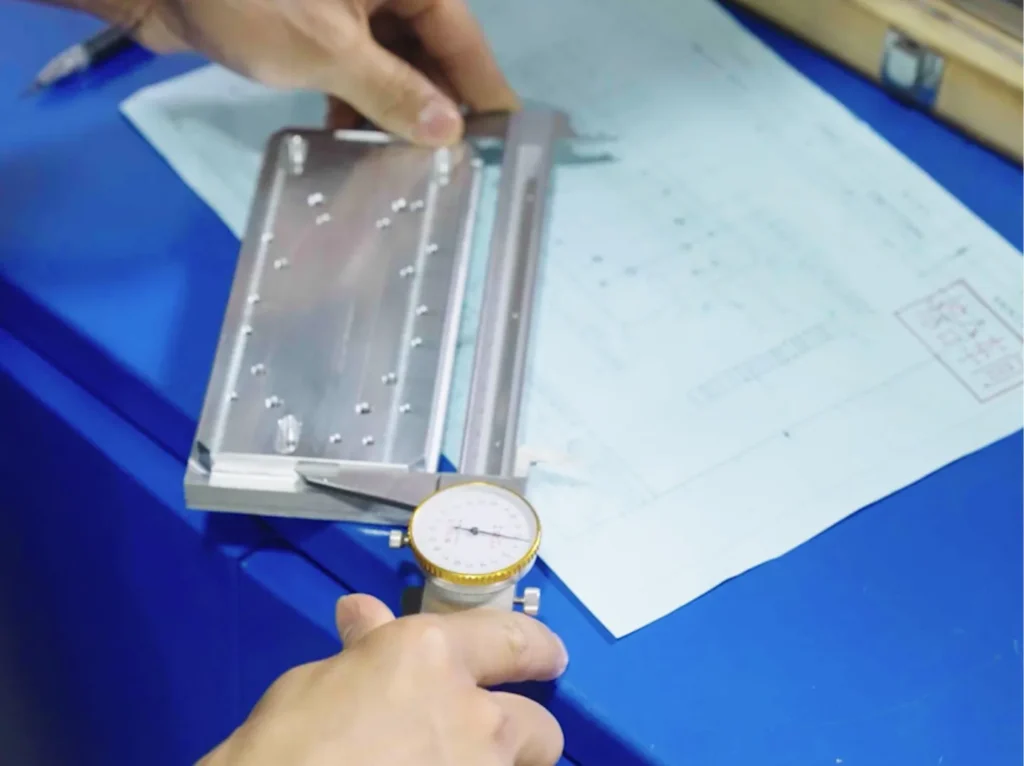

1. Critical Dimension Measurement

Use precision measuring tools such as calipers, micrometers, coordinate measuring machines (CMM), and profile projectors to check key dimensions such as length, diameter, hole spacing, and slot width.

Critical dimensions (e.g., shaft diameters, hole distances, gear module) must meet specifications, even if other dimensions are within tolerance, nonconformance of these critical dimensions may prevent proper assembly or cause operational issues.

2. Tolerances and Geometric Tolerances

- Linear tolerances: Verify that part dimensions fall within the allowable ranges specified on the drawings.

- Geometric tolerances: Including parallelism, perpendicularity, coaxiality, roundness, etc., which are especially important for high-precision parts.

Noncompliance with geometric tolerances may result in excessive or insufficient clearance, affecting assembly accuracy and operational stability.

3. Hole Locations and Threads

Hole positions, diameters, and depths must strictly follow design requirements to ensure proper alignment with mating components.

Threaded features must meet specification requirements, with smooth engagement and no binding, ensuring ease of assembly and disassembly.

For high-precision assembly holes, verification can be performed using plug gauges, ring gauges, or thread gauges.

Ⅲ. Material and Performance Verification

The material and performance of a part directly affect its strength, wear resistance, corrosion resistance, and overall lifespan. When inspecting machined parts, clients should focus on the following aspects:

1. Material Verification

- Check the Material Certificate to ensure the part uses the specified material according to the drawing.

- For critical or high-value parts, chemical composition analysis or spectrometry may be required to confirm the material meets standards.

- Using the wrong material can result in insufficient strength or poor wear resistance, compromising the overall reliability of the product.

2. Hardness and Heat Treatment Inspection

- Perform hardness tests (Rockwell, Brinell, or Vickers) on load-bearing or stress-prone parts.

- Verify heat treatment processes, such as quenching and tempering, to ensure the part’s strength, toughness, and durability meet design requirements.

- Improper heat treatment can cause cracking, deformation, or reduced service life.

3. Surface Treatment Verification

- For anodized, coated, or plated parts, inspect for uniform coating thickness and ensure there is no peeling, bubbling, or porosity.

- For corrosion-resistant parts, simple salt spray or chemical corrosion tests may be performed.

- The quality of surface treatment directly affects wear resistance, corrosion resistance, and appearance.

IV. Functional and Assembly Verification

Even if a part’s appearance is good and its dimensions meet the requirements, its performance in actual use cannot be guaranteed. Therefore, functional and assembly verification are essential components of machined part acceptance.

1. Dimensional Fit and Assembly

Verify that the part can be smoothly assembled with its mating parts, ensuring that clearances and fit tolerances meet design requirements.

For critical interfaces such as sliding fits, interference fits, or threaded fits, actual assembly smoothness testing is required.

Check for binding, looseness, or interference during assembly to avoid problems in subsequent production or use.

2. Motion and Force Testing

Perform rotational and sliding tests on moving parts (such as gears, bearings, and slide rails) to observe smooth operation and abnormal noise.

For load-bearing parts, perform static or simple dynamic load tests to ensure stability and reliability under the designed loads.

For high-precision or high-speed moving parts, functional performance can be verified through experiments simulating actual operating conditions, if necessary.

3. Special Function Inspection

Inspect the parts to ensure that their special functions, such as waterproofing, corrosion resistance, high-temperature resistance, and wear resistance, meet design standards.

For functional parts, on-site testing can be conducted based on actual customer usage scenarios to ensure that the parts function properly in real-world environments.

V. Recommended Customer Inspection Process

To ensure part quality, clients can follow the following systematic process when inspecting machined parts:

1. Drawing Confirmation

- Verify the version of the part drawing and key requirements, including dimensions, tolerances, materials, and functional specifications.

- Confirm any special requirements on the drawing (e.g., surface treatment, heat treatment, or functional indicators) to avoid omissions during inspection.

2. Sample Part Inspection

- Before mass production, inspect a single sample part.

- Focus on dimensions, surface finish, functionality, and assembly fit to ensure machining quality meets standards.

3. Batch Sampling Inspection

- For large production runs, conduct sampling inspection according to standard sampling ratios (e.g., ISO 2859-1).

- Sampling should include key dimensions, tolerances, functional performance, and appearance to ensure overall consistency of the batch.

4. Record Keeping

- All measurement data, material certificates, and inspection results should be fully documented and retained.

- This facilitates traceability, quality analysis, and communication with the machining factory.

5. Communication and Feedback

- Any issues found during inspection should be promptly communicated to the machining factory with adjustment requests.

- Feedback should detail the problem areas, quantities, and specific nonconformities to enable quick corrective action by the supplier.

VI. Inspection Considerations

Clients should pay attention to the following points during machined part inspection to ensure effective and accurate acceptance:

- Prioritize Critical Parts

Load-bearing, moving, or safety-related parts should be inspected more rigorously, with full inspection or additional performance testing if necessary. - Use Appropriate Measuring Tools

Choose calipers, micrometers, or CMMs according to part precision to avoid measurement errors affecting inspection results. - Lighting and Environment

Perform appearance checks under good lighting, using uniform light sources or magnifiers if needed to detect minor defects.

High-precision dimensional measurements should be conducted in a temperature-controlled environment to avoid errors due to thermal expansion or contraction. - Preserve Inspection Evidence

Take photos or record measurement data to facilitate communication with the supplier and serve as evidence for quality traceability and future improvements. - Focus on Batch Consistency

In addition to sample inspection, perform representative sampling on batch parts to ensure overall quality consistency and prevent localized defects from affecting assembly and performance.

Summary

By following a systematic inspection process, clients can comprehensively control the quality of machined parts, ensuring that every part meets design standards in terms of appearance, dimensions, material, functionality, and assembly performance. YPMFG CNC Machining Factory is committed to providing high-precision, reliable, and durable machined parts, while offering professional inspection guidance to help clients reduce production risks and improve product quality and user experience.