When sourcing mechanical components, finding a reliable machining factory is essential to ensure product quality and on-time delivery. A good supplier not only delivers high-precision parts on schedule but also provides technical support and services that help customers reduce costs and improve competitiveness.

Here are 10 key points of a quality machining factory that procurement teams can use as a reference when evaluating potential suppliers.

1. Complete Certifications and Solid Reputation

The first step in assessing a supplier is checking its certifications and reputation. A qualified machining factory should hold a valid business license and industry-recognized certifications such as ISO9001, IATF16949, or ISO 14001. These certifications demonstrate standardized processes in manufacturing and quality control.

Additionally, reputable factories often have a proven track record with well-known customers and can provide references or third-party inspection reports. This demonstrates their ability to deliver consistent, long-term supply.

2. Advanced Equipment and Strong Capabilities

A factory’s equipment defines its machining capabilities. Leading machining companies typically operate CNC lathes, five-axis machining centers, mill-turn machines, and grinding machines. They are capable of producing everything from simple components to highly complex parts.

They also handle a wide range of materials, including aluminum, stainless steel, titanium cnc machining, copper, and engineering plastics. The more advanced the equipment and processes, the better they can meet diverse, high-precision demands.

3. Strict Quality Control

High-quality machining factories establish comprehensive quality control systems. They implement rigorous incoming inspections, in-process checks, and final inspections to ensure every stage meets the required standards.

Advanced inspection tools such as CMMs, height gauges, and projectors are commonly used, along with detailed reports (e.g., dimensional reports, PPAP, or FAI). Such quality assurance practices minimize the risk of nonconforming parts reaching the customer.

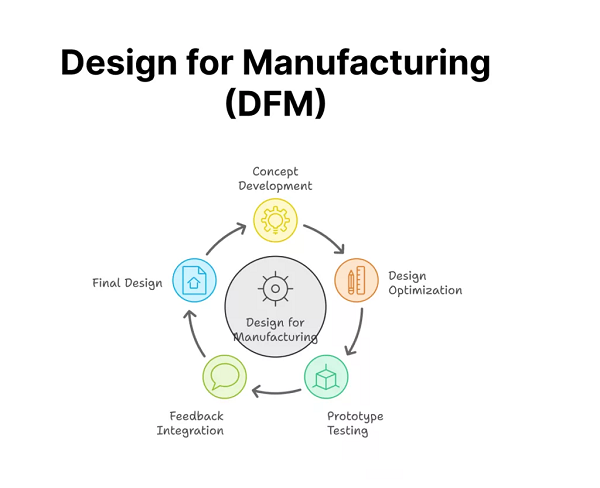

4. Professional Engineering Team

A reliable machining factory does more than follow drawings—it provides process optimization and technical support. Skilled engineers can quickly interpret complex designs and suggest design-for-manufacturing (DFM) improvements, helping reduce machining challenges and costs.

When issues arise, a professional team communicates promptly and resolves problems proactively, reflecting both expertise and accountability.

5. Reliable Lead Times and Fast Response

On-time delivery is a top priority for buyers. A dependable factory manages capacity effectively to ensure punctual delivery and prevent delays caused by poor scheduling or limited resources.

They also have flexible scheduling capabilities to handle urgent orders, enabling customers to stay competitive in fast-moving markets.

6. Transparent and Competitive Pricing

While cost is important, transparency signals professionalism. Reliable suppliers provide clear quotations, breaking down material, machining, and finishing costs, without hidden fees.

They also offer optimized pricing based on volume and process requirements. This not only helps customers save money but also demonstrates a commitment to long-term partnerships.

7. Comprehensive Finishing and Secondary Services

Many parts require additional treatments such as anodizing, plating, coating, or heat treatment. A factory that offers integrated finishing services reduces the need for outsourcing, minimizing risks of quality variation and lead-time delays.

This one-stop capability simplifies project management and ensures more consistent results.

8. Smooth Communication and Strong Customer Service

Effective communication is essential for successful collaboration. Quality factories assign dedicated sales or project managers who respond quickly and maintain transparency throughout the process.

For international clients, strong English communication skills are a must. The smoother the communication, the easier the cooperation, and the more stable the partnership.

9. Adequate Scale and Long-Term Stability

A factory’s scale and stability are critical factors. Facilities with their own workshops, advanced equipment, and long-term employees are far more reliable than small workshops.

They can handle both prototype and large-scale production while maintaining consistent quality and supply over the long term, reducing procurement risks.

10. Continuous Improvement and Partnership Mentality

Outstanding machining factories focus not just on single orders but on long-term cooperation. They invest in new equipment, adopt advanced processes, and continuously optimize production to improve efficiency and quality.

They actively listen to customer needs and seek win-win solutions, making them the kind of partners that buyers can rely on for years.

Conclusion

When selecting a machining supplier, buyers should look beyond price and evaluate factors such as certifications, equipment, quality, lead time, service, and stability. Through on-site audits, small trial orders, and multi-dimensional evaluations, companies can significantly reduce risks and identify truly reliable partners.

If you are looking for a trusted CNC machining partner, we welcome you to get in touch. YPMFG Machining is equipped with advanced machinery, a strict quality management system, and an experienced engineering team. We provide one-stop machining solutions, from rapid prototyping to full-scale production. With a focus on precision, quality, and on-time delivery, we are committed to being your long-term, reliable manufacturing partner.