Face milling is indispensable in the metalworking industry, which is undergoing significant transformation. Without face milling, the complexity of machining processes would be unimaginable. This technique achieves precision and surface quality improvements by generating flat surfaces to complete reference surfaces. Furthermore, the production of many rotating components remains incomplete without face milling. Clearly, the importance of face milling cannot be underestimated.

Table of Contents

1. What Is Face Milling?

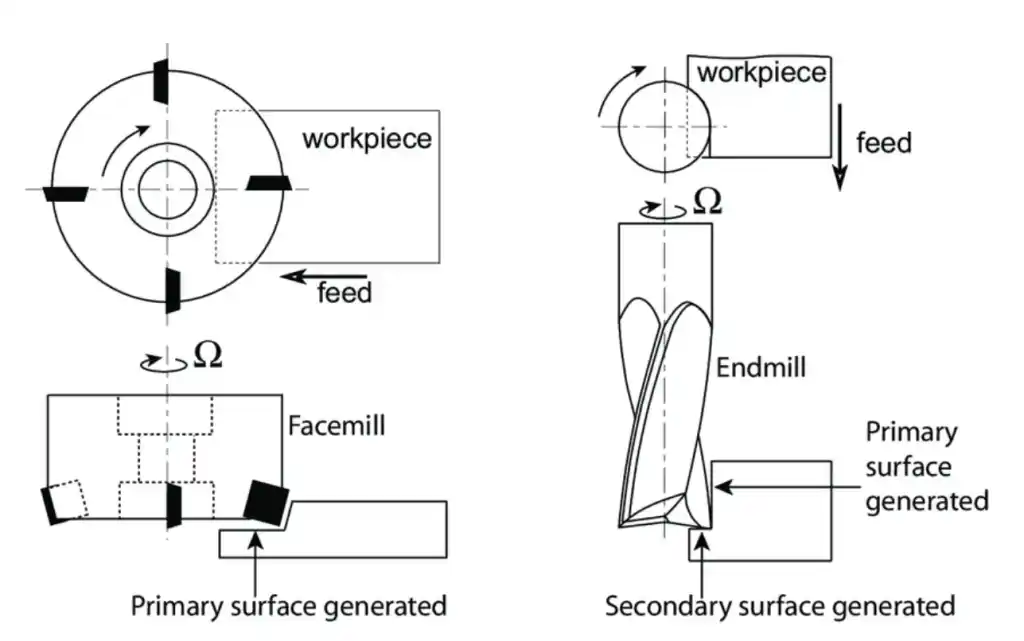

Face milling is a type of CNC milling process, meaning it involves using cutting tools to remove material from a workpiece. However, unlike conventional milling, this process requires positioning the cutting tool so that its rotational axis (or tool axis) is perpendicular to the workpiece. Note how the multi-tooth cutting tool is positioned facing downward toward the top of the workpiece. As the workpiece passes through the cutting tool, material is removed by rotating the cutting tool counterclockwise.

2. Applications of Face Milling

1. Creating Flat Surfaces

Face milling is most commonly used to produce flat, level surfaces on workpieces. This step often serves as the foundation for further machining operations, providing a precise reference surface that ensures overall part quality and accurate assembly fit.

2. Surface Preparation for Subsequent Machining

Before operations such as pocket milling, drilling, or profile cutting, face milling smooths and levels the workpiece’s top surface. This preparation reduces tool wear in later steps and improves dimensional accuracy.

3. Improving Surface Finish

Face milling produces finer surface finishes compared to many other machining methods. The use of overlapping cutting paths and multiple inserts helps minimize post-processing such as grinding or polishing, making it ideal for parts that require high-quality finishes.

4. Squaring Up Workpieces

Face milling can also square the sides of blocks or plates, ensuring workpieces are accurate and repeatable. This improves alignment in fixtures and prevents dimensional errors in subsequent machining.

5. Industry Applications

Automotive: Surfacing cylinder heads, engine blocks, and base plates.

Aerospace: Preparing large aluminum and titanium components with tight tolerances.

Mold and Die Making: Producing flat, precise surfaces on mold bases and inserts.

General Manufacturing: Leveling steel, aluminum, or plastic stock before machining complex geometries.

3. Face Milling vs. Peripheral Milling: What’s the Difference?

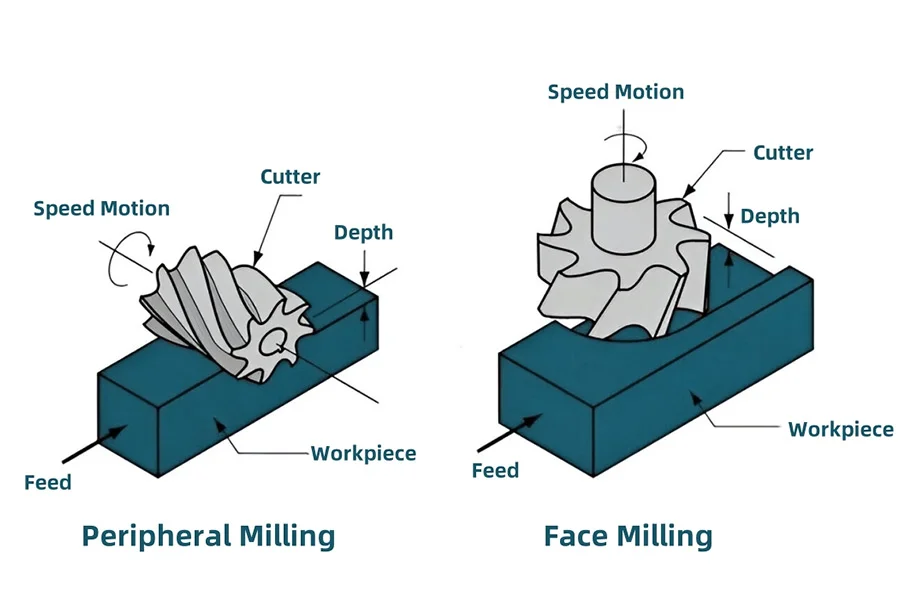

Face milling and peripheral milling are two primary types of milling operations. Their operational modes are very similar, but they differ in setup and suitability for manufacturing features. For example, in peripheral milling, the cutting tool is positioned parallel to the workpiece, as shown below. The unique configuration of peripheral milling ensures the tool’s flank grinds away the top surface of the workpiece. Consequently, peripheral milling can efficiently remove large volumes of material from the workpiece. In contrast, face milling uses the tool tip to remove small amounts of material, making it more suitable for applications requiring fine surface finishes.

4. Tools for Face Milling

Face milling processes can precisely produce various parts and features. However, the success of this process also depends on selecting the ideal face milling cutter. Let’s examine three common types of cutters.

1. End Mills

End mills typically feature cutting edges (or flutes) on both their tip and shank, designed to create flat surfaces along the axis of a high-speed rotating spindle. This unique design makes them ideal for creating intricate patterns, small faces, contours, and grooves during the surface finishing stage of product development. However, you may find them inefficient when needing to remove large volumes of material during the initial machining phase.

2. Shell Mill

Shell mills are the most commonly used tools for face milling. These cutting tools feature multiple cutting teeth and inserts on their outer edge, as shown below. The unique design of shell mills provides balanced cutting forces and precise control over the amount of material removed during high-speed cutting. Consequently, machinists often select end mills to achieve high-quality, consistent surface finishes. However, end mill inserts may occasionally require replacement based on the workpiece material.

3. Plunge Cutter

A plunge cutter is a single-point cutting tool primarily used for machining large surfaces. “Single-point” refers to the tool having one cutting edge that removes material in a single pass. Unlike end mills and end mill inserts, which deliver impressive cutting and surface finish at high speeds, fly cutters achieve superior cutting and surface finish at lower speeds. This means machinists using fly cutter machines require less power to achieve high-quality cuts. Machinists typically choose fly cutters when seeking excellent surface finish and speed is not a primary concern.

5. The Face Milling Process

1. Workpiece Arrangement and Clamping

Clean the workpiece to remove chips, burrs, or oil.

Secure it firmly using a vise, parallels, or clamps.

Ensure the part is flat, level, and rigid to prevent vibration.

2. Tool Positioning and Alignment

Mount the face milling cutter correctly and check inserts.

Align the spindle perpendicular to the workpiece surface.

Set the tool height (Z-zero) carefully using a touch-off or probe.

3. Setting Spindle Speed and Feed Rate

Adjust spindle speed and feed rate based on the workpiece material, cutter type, and desired finish.

Choose appropriate depth of cut for roughing or finishing.

4. Performing the Machining

CNC: Dry-run first, confirm offsets, run the program with coolant, and monitor the first pass.

Manual: Steady feed, align the cutter carefully, avoid dwell, and ensure proper chip removal.

5. Finishing and Inspection

Take a light finishing pass if needed for high surface quality.

Deburr edges and inspect the surface for flatness and finish.

6. Face Milling Techniques

When performed by skilled machinists adhering to fundamental principles, face milling offers an effective method for achieving high precision and cost-effective production. Top-tier machinists follow these essential techniques during the process:

Use recommended spindle speeds to prevent tool wear.

Always position the cutting tool offset from the workpiece center, as this produces thin chips—the excess material generated as a byproduct of face milling operations. This orientation ensures cleaner cuts and finer surface finishes.

Avoid frequent tool entries and exits, as this can induce stress on cutting edges and compromise part accuracy.

Refrain from milling operations on slots or holes, as these edges also necessitate multiple tool entries and exits. Automate the cutting process using computer numerical control (CNC) technology to achieve highly precise components.

7. Types of Face Milling Operations

Face milling is a versatile machining operation, and its approach can be adjusted depending on the material, part size, machine capability, and desired finish. Below are the main types of face milling operations:

1. General Face Milling

Description: This is the standard face milling operation used to create flat, level surfaces.

Tooling: Typically uses cutters with a 45° entering angle.

Applications: Suitable for a wide range of materials, including aluminum, steel, and plastics.

Advantages: Provides a balanced distribution of cutting forces, achieving a good surface finish without overloading the tool or machine.

Use Case: Preparing a raw metal plate for further machining or leveling the top face of a block.

2. Heavy-Duty Face Milling

Description: Designed for removing large amounts of material quickly.

Tooling: Tools often have higher entering angles, such as 60°, which direct cutting forces more axially, improving stability.

Machine Requirements: Requires rigid machines with high spindle power and stable fixturing.

Advantages: High material removal rate with reduced vibration, suitable for large workpieces.

Use Case: Machining thick steel plates, engine blocks, or large structural components where bulk material removal is necessary before finishing.

3. High-Feed Milling

Description: Uses shallow depths of cut but very high feed rates.

Tooling: Low entering angles (around 10°) are used to reduce radial cutting forces.

Advantages: Allows rapid machining with minimal tool wear, maintains tool stability, and reduces cutting pressure.

Applications: Works well for long, flat surfaces or high-volume production where speed is critical.

Use Case: Aluminum panels, large flat metal sheets, or high-productivity operations in automotive and aerospace industries.

4. Finishing with Wiper Inserts

Description: A finishing operation that uses specially shaped inserts called wiper inserts.

Advantages: Improves surface finish without reducing feed rate, allows higher feed per tooth while maintaining a smooth surface.

Tooling: Wiper inserts often replace standard inserts in shell mills.

Applications: High-precision finishing where surface quality is critical, often in molds, dies, and aerospace components.

Use Case: Final finishing of a flat surface before assembly or coating to ensure smoothness and tight tolerances.

8. Advantages and Disadvantages of Face Milling

Face milling is widely used in manufacturing due to its efficiency, precision, and versatility. Like any machining process, it offers both benefits and limitations.

Advantages

High-Quality Surface Finish: Produces smooth, consistent surfaces with minimal post-processing. Overlapping cutting paths and multiple inserts help achieve fine finishes.

Versatility Across Materials: Works on metals (steel, aluminum, titanium), plastics, and composites. Compatible with various cutting tools and insert materials.

Efficient Material Removal: Supports high feed rates, especially with multi-insert cutters, and is suitable for both roughing and finishing.

Reduced Chatter and Tool Load: Proper tool geometry and feed rates balance radial and axial forces, lowering vibration risk.

Dimensional Accuracy: Ensures flat, level surfaces and precise tolerances, ideal for preparing workpieces for further machining.

Flexibility in Tool Choice: Offers end mills, shell mills, and fly cutters. Tool size, coating, number of flutes, and cutting angles can be adjusted.

Reduced Entry and Exit Impact: Correct lead angles and cutting strategies minimize burring or edge breakout.

Disadvantages

Limited to Surface Features: Cannot machine internal corners, slots, steep vertical walls, or complex 3D geometries.

Tool Clearance Issues: Large face mills may interfere with fixturing or nearby features, especially in tight spaces.

Burring and Chipping: Can occur at the cutter exit point if feed or speed is incorrect, particularly on hard materials.

Lead Angle Limitations: Maximum axial depth of cut per pass is restricted by the cutter’s lead angle.

Higher Initial Tool Cost: Specialized face milling cutters are more expensive than simpler tools, though their efficiency and versatility justify the investment.

9. Cost and Efficiency

Face milling tools may have higher upfront costs than simpler cutters, but their durability and versatility make them cost-effective over time. One tool can handle multiple materials and operations, reducing the need for extra cutters. Face milling also produces smooth, flat surfaces with minimal post-processing, saving time, labor, and improving overall production efficiency.

10. Conclusion

Face milling is a versatile, efficient machining process for producing flat, smooth surfaces with high precision. It requires proper workpiece clamping, cutter alignment, and adjustment of spindle speed and feed. Common tools include end mills, shell mills, and fly cutters, while typical operations include general, heavy-duty, high-feed, and finishing with wiper inserts. The process delivers excellent surface finish, efficient material removal, dimensional accuracy, and versatility across a wide range of materials. Its limitations include inability to machine internal corners or steep vertical walls and the need for specialized tooling.

At YPMFG, we offer professional CNC machining services, including face milling. Our team provides expert guidance on tool selection, cutting parameters, and material choice to ensure high-quality results. Whether for prototypes or full production runs, we help optimize efficiency, reduce costs, and achieve precise finishes. Contact YPMFG today to discuss your machining needs and request a free quote.