Lightweighting has become one of the core objectives in modern engineering structure design. Especially in the fields of aerospace, transportation, robotics, consumer electronics, etc., how to ensure sufficient rigidity while reducing weight has become the key to material selection. At this time, “Specific Stiffness” as an important index to measure the stiffness of a material per unit mass has a very high reference value.

Table of Contents

I. What is Specific Stiffness?

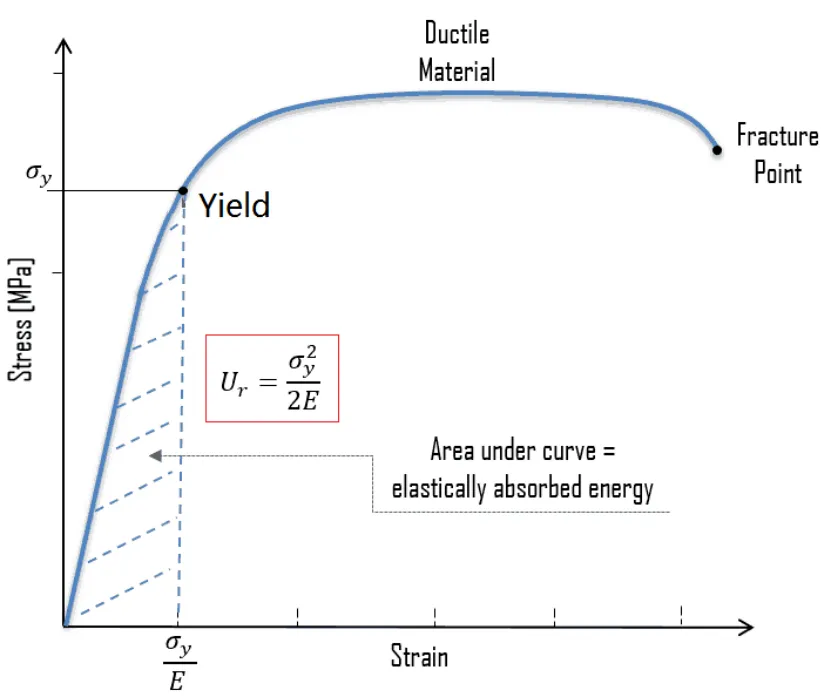

Specific Stiffness = Modulus of Elasticity / Density

The unit is often expressed as GPa/(g/cm³) or MN-m/kg.

- Elastic Modulus: The ability of a material to resist elastic deformation.

- Density: the mass per unit volume of a material.

The higher the specific stiffness, the more rigid the material is for a given mass. Therefore, in weight-sensitive structures, specific stiffness is one of the key considerations in material selection.

Ⅱ. Key Factors Affecting Specific Stiffness

1. Modulus of elasticity: influenced by the strength of the atomic bonds, e.g., beryllium’s covalent bonds give it an extremely high modulus of elasticity.

2. Density: Lightweight elements such as beryllium (Be), magnesium (Mg), and aluminum (Al) are more likely to have high specific stiffness.

3. Microstructural design: Performance can be further enhanced by alloying, heat treating or introducing ceramic reinforcement.

Ⅲ. Top 10 Metals Ranked by Specific Stiffness

1. Beryllium (Beryllium)

- Specific stiffness: ~287 GPa/(g/cm³) (the most metal)

- Characteristics: Modulus of elasticity up to 287 GPa, but density only 1.85 g/cm³.

- Applications: spacecraft structural components, satellite mounts, precision optical platforms.

- Note: Highly toxic, processing requires protection.

2. Magnesium Alloys (MAGNESIUM ALLOYS)

- Specific stiffness: ~25-45 GPa/(g/cm³).

- Characteristics: Density of only 1.74 g/cm³, one of the lightest engineering metals, with significant performance gains after alloying.

- Applications: laptop housings, car wheels, drone frames.

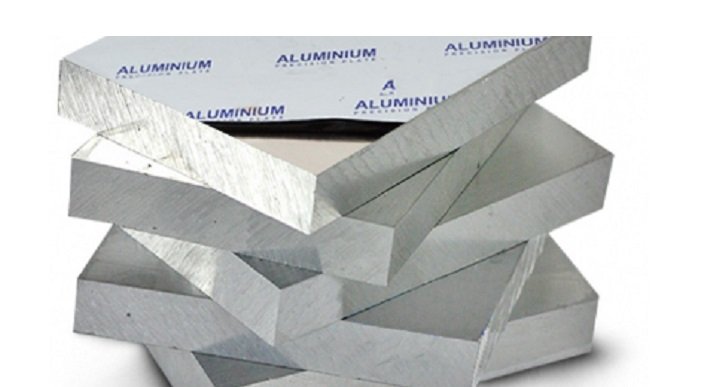

3. Aluminum Alloys (e.g., 7075-T6)

- Specific stiffness: ~25-26 GPa/(g/cm³)

- Characteristics: Modulus of elasticity ~70 GPa, low density (2.8 g/cm³), good strength and corrosion resistance.

- Applications: spacecraft, airplane fuselage, bicycle frames, mechanical structural parts.

4. Titanium Alloys (e.g., Ti-6Al-4V)

- Specific stiffness: ~24 GPa/(g/cm³)

- Characteristics: High modulus of elasticity (~110 GPa), medium density (4.43 g/cm³), combines high strength and corrosion resistance.

- Applications: aircraft engines, structural supports, medical implants.

5. Scandium-Aluminum Alloys (Scandium-Aluminum Alloys)

- Specific Stiffness: ~23-24 GPa/(g/cm³)

- Characteristics: A small amount of scandium can significantly improve the rigidity and weldability of aluminum alloys.

- Applications: spacecraft, high-end sports equipment (e.g., tennis rackets, bicycles).

- Remarks: Scandium resources are scarce, and the cost is high.

6. High-Entropy Alloys (e.g., AlCoCrFeNi)

- Specific Stiffness: ~20-22 GPa/(g/cm³)

- Characteristics: Composed of a variety of major elements with good stiffness, strength and thermal stability.

- Applications: Materials for extreme temperatures or corrosive environments, future candidates for new materials for aerospace.

7. Aluminum-Lithium Alloys (e.g., AA2099)

- Specific stiffness: ~20-21 GPa/(g/cm³)

- Characteristics: The addition of lithium dramatically reduces the density while slightly increasing the modulus of elasticity.

- Applications: Boeing and Airbus for new generation aircraft skin and girder structures.

8. Nickel-Based Superalloys (e.g., Inconel 718)

- Specific stiffness: ~18-19 GPa/(g/cm³)

- Characteristics: Extremely high modulus of elasticity despite high density (~8.2 g/cm³) for high-temperature strength-demanding environments.

- Applications: turbine blades, nuclear power equipment, rocket nozzles.

9. High-Strength Steel (e.g., Maraging Steel)

- Specific Stiffness: ~18 GPa/(g/cm³)

- Characteristics: Highest modulus of elasticity among metals (~210 GPa), but also high density (~7.8 g/cm³).

- Applications: molds, structural beams, rail transportation, military armor.

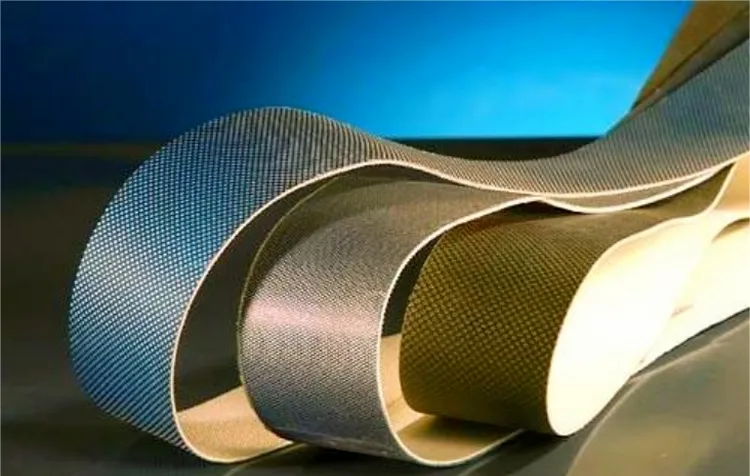

10. Metal Matrix Composites (e.g., Al/SiC)

- Specific Stiffness: ~30-50 GPa/(g/cm³) (not pure metal)

- Characteristics: Reinforced by ceramic (e.g., SiC) particles, which can significantly increase stiffness with a small density increase.

- Applications: High precision instruments, satellite platforms, space alignment structures.

Ⅳ. Summary and Material Selection Advice

Magnesium and aluminum alloys are cost-effective choices for lightweight engineering materials, and are particularly well suited for weight-sensitive structures with moderate strength requirements, such as automotive, consumer electronics, and aerospace structures. Titanium alloys, on the other hand, excel in balancing strength, stiffness, and corrosion resistance, and are suitable for demanding applications such as aircraft engines and medical implants.

Scandium-aluminum alloys outperform conventional aluminum alloys in terms of performance, but because scandium is rare and expensive, they are mainly used for high-end custom applications, such as high-performance sports equipment or aerospace-critical structures.

High-entropy alloys and metal matrix composites represent the future direction of materials development, with good potential for performance modulation, especially for advanced equipment in extreme environments. However, they are still in the R&D or small-scale application stage.

Although nickel-based superalloys and high-strength steels have obvious disadvantages in terms of density, they still play a key role in turbines, military structures and heavy-duty components due to their excellent high-temperature performance and strength.

In summary, when selecting structural materials, the specific stiffness, weight, cost, corrosion resistance, machinability and long-term reliability of the material should be weighed against the specific application environment:

- For extreme lightweight + high rigidity: beryllium and scandium aluminum alloys are preferred.

- For a balance between lightweight and cost-effectiveness, magnesium alloys and aluminum alloys are preferred.

- For strength, corrosion resistance and rigidity: consider titanium alloys.

- For extreme environments (high temperature, corrosion): nickel-based superalloys or high-entropy alloys.

- If sensitive to both rigidity and cost, composites can be an alternative.

No one material is suitable for all scenarios. The key to engineering material selection is “demand-oriented + performance balance”.