Table of Contents

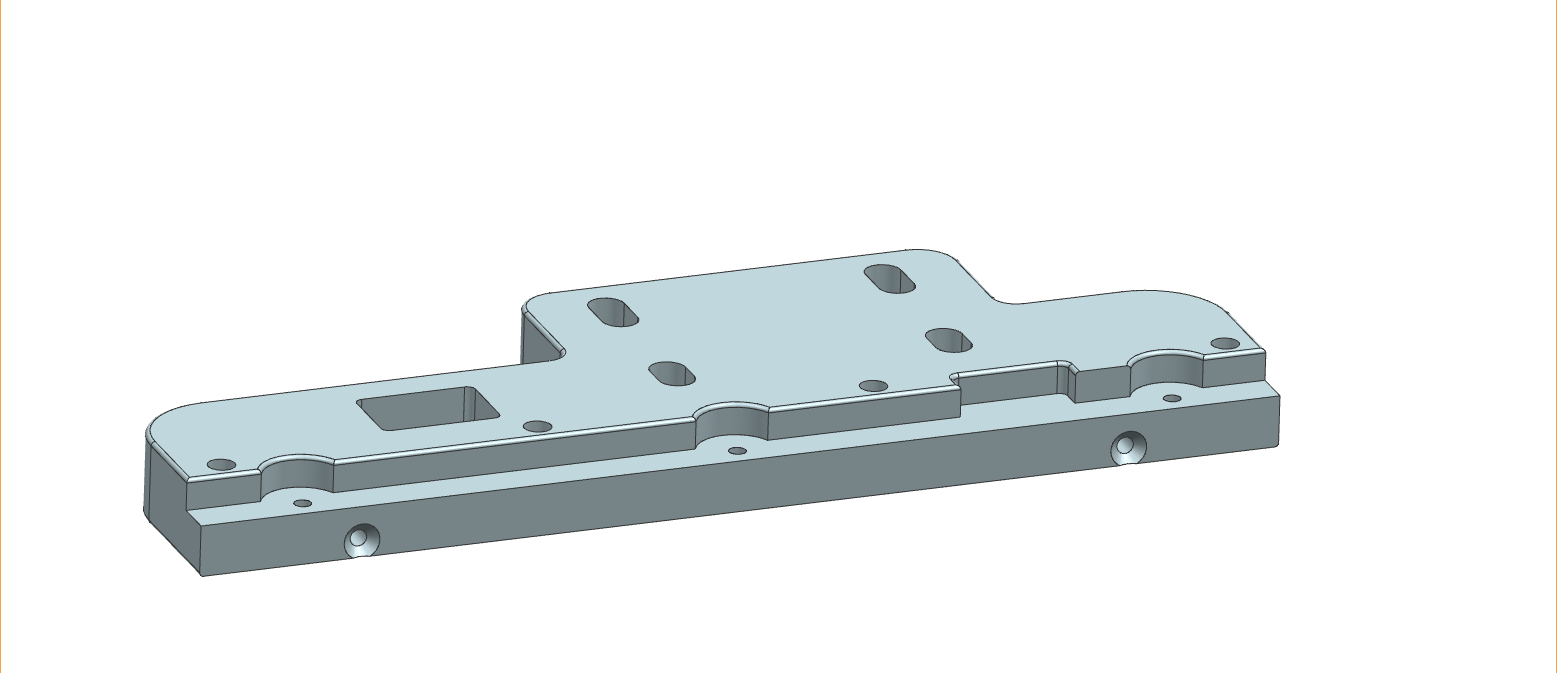

Aluminum Alloy

Overview Aluminum Alloy Definition

Aluminum alloy is an alloy material formed by adding a certain amount of other alloying elements (e.g., copper, manganese, silicon, magnesium, zinc, etc.) to aluminum as a matrix. Due to the addition of alloying elements, aluminum alloys have higher strength, better casting and machining properties, and excellent corrosion resistance while maintaining the basic properties of aluminum, such as light weight and good electrical and thermal conductivity.

Classification of Aluminum Alloys

Aluminum alloys are mainly divided into two categories according to their composition and processing methods: deformed aluminum alloys and cast aluminum alloys.

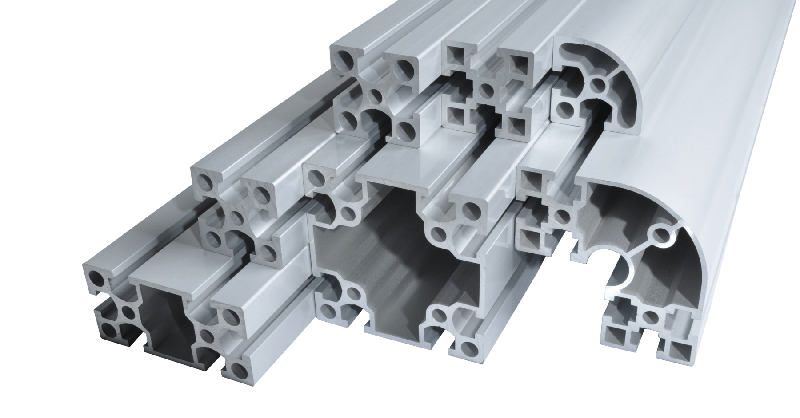

Deformed aluminum alloys: These alloys are made into products of various shapes through plastic deformation processing, such as rolling, extrusion, stretching, forging and other methods. Deformed aluminum alloy has better mechanical properties and processing performance, widely used in aerospace, transportation, building structures and other fields.

Casting Aluminum Alloy: Directly cast into blanks of various parts through melting, with excellent casting performance and mobility. Casting aluminum alloys are suitable for the manufacture of complex shapes and thin-walled parts.

1-8 Series Aluminum Alloys

Overview: Aluminum alloys are divided into 1 to 8 series according to international standards, and each series of alloys has its own specific composition and performance characteristics:

1XXX series: pure aluminum, with aluminum content of 99.00% or more, has the best thermal conductivity and good corrosion resistance, but the strength is relatively low.

2XXX series: copper as the main alloying element, with high strength, but poor corrosion resistance, mainly used in the aviation industry. 3XXX series: copper as the main alloying element, with high strength, but poor corrosion resistance, mainly used in the aerospace industry. Aviation industry.

3XXX series: Manganese as the main alloying element, with good rust resistance and processability, is commonly used in building decoration and chemical equipment.

4XXX series: Silicon as the main alloying element, with high strength and good weldability, suitable for welded structures. 5XXX: Magnesium, as the main alloying element, with low density and high strength, is commonly used in ship and vehicle structures.

5XXX series: Magnesium, as the main alloying element, with low density and high strength, is commonly used in ship and vehicle structures.

6XXX series: Magnesium, as the main alloying element, with low density and high strength, is commonly used in ship and vehicle structures.

6XXX series: with magnesium and silicon as the main alloying elements, it has good processing performance and welding performance, and is widely used in structural materials.

7XXX series: with zinc as the main alloying element, it has the highest strength but poor corrosion resistance, and is mainly used in ultra-high-strength structures.

8XXX series: it contains other alloying elements such as lithium and iron, and has special properties such as high stiffness and good heat resistance.

The wide range of applications and characteristics of aluminum alloy materials make them one of the indispensable materials for modern industry. With the development of science and technology and the improvement of material performance requirements, the research and application of aluminum alloy will continue to deepen and expand its application in various fields.

Series 1 Aluminum Alloy Properties and Applications

Chemical Composition and Physical Properties

Series 1 Aluminum Alloy, as the highest purity aluminum alloy series, has a chemical composition of mainly aluminum with an aluminum content of 99.00% or more. This series of alloys is usually represented by grades such as 1050, 1070, 1100, etc., which exhibit excellent electrical and thermal conductivity and corrosion resistance in their physical properties. Due to their high purity, Series 1 aluminum alloys have a low density, usually around 2.7 g/cm³, which gives them a weight advantage and makes them widely used in applications requiring lightweight materials.

The electrical and thermal conductivities of Series 1 aluminum alloys can reach about 61% and 50% of the international standard conductivity for annealed copper, respectively, which makes them very popular for use in cable fabrication and heat sink parts. In addition, the corrosion resistance of Series 1 aluminum alloys is mainly due to the formation of a dense oxide film on the surface, which effectively prevents further oxidation and corrosion.

| Alloy Series | Alloy Number | Material Characteristics Summary | |

| JIS | A.A | ||

| 1000 Series | 1060 | 1060 | Used as electrical conductive material, IACS guaranteed at 61%. Use 6061 when strength is needed. |

| 1085 1080 1070 1050 1N30 | 1085 1080 1070 1050 – | Good formability and surface treatment properties. Among aluminum alloys, it has the best corrosion resistance. Being pure aluminum, its strength is relatively low. The higher the purity, the lower the strength. | |

| 1100 1200 | 1100 1200 | General-purpose aluminum materials with purity over 99.0%. After anodizing, the appearance is slightly white, similar to the above. | |

| 1N00 | Slightly stronger than 1100, good formability, other chemical properties are similar to 1100. | ||

Formability and Surface Finish

Series 1 aluminum alloys have excellent formability, thanks to their low melting point and good plasticity. They can be formed into plates, tubes, bars, etc. by various plastic processing methods such as rolling, extruding and drawing. During the forming process, Series 1 aluminum alloys have low rebound and are easy to control the shape, making them suitable for manufacturing complex parts.

For surface treatment, Series 1 aluminum alloys can be treated by anodizing, plating, and spraying to obtain the desired appearance and performance. Anodizing is the most common surface treatment, which not only improves the corrosion resistance of the material but also gives the material a variety of colors and enhances its decorative properties.

Series 1 aluminum alloy has good surface treatment, and can be treated with chemical sanding, glossy, matte, etc., to meet the needs of different application scenarios.1 series aluminum alloy has a wide range of applications in the fields of architectural decorations, electronic equipment, and automobile manufacturing due to its formability and surface treatment. The formability and surface treatment of Series 1 aluminum alloy make it widely used in building decoration, electronic equipment, automobile manufacturing and other fields. For example, 1100 grade aluminum alloys are commonly used for beverage cans and food packaging materials due to their good formability and surface finish. Grades such as 1050 and 1070 are commonly used in the production of cable jackets and decorative panels.

Series 2 Aluminum Alloy Characteristics and Applications

Chemical Composition and Physical Properties

Series 2 aluminum alloys, with copper as the main alloying element, the copper content in their chemical composition is generally between 3% and 5%, representative grades include 2014, 2024, etc. The physical properties of this alloy are mainly reflected in its high strength and good machinability. The physical properties of this alloy are mainly reflected in its high strength and good machinability. 2 series aluminum alloys have a density of about 2.78 g/cm³, which is slightly higher than that of 1 series aluminum alloys, but the strength is significantly higher, with a σb value of more than 400 MPa.

The heat treatment effect of the 2 series aluminum alloy is remarkable, and its mechanical properties can be further improved by solid solution treatment and aging treatment. Solid solution treatments can bring the strength of the alloys up to or even beyond that of mild steel, while aging treatments further enhance the yield strength through a precipitation hardening mechanism, although this may be at the expense of a certain amount of elongation.

In terms of electrical and thermal conductivity, Series 2 aluminum alloys are not as good as Series 1 aluminum alloys, but they still maintain the excellent characteristics of aluminum materials, with electrical conductivity reaching about 40% of the international standard conductivity for annealed copper. In addition, 2 series aluminum alloys have a strong work hardening ability, and their strength can be further improved by cold working.

| Alloy Number | Material Characteristics Summary | |

| JIS | A.A | |

| 2011 | 2011 | Fast cutting alloys, good cutting strength is also high. But the corrosion resistance is not good. Requirements for corrosion resistance, the use of 6062 series alloys. |

| 2014 2017 2024 | 2014 2017 2024 | Containing a large amount of Cu, the corrosion resistance is not good, but the strength is high, so it can be used as structural material. It can also be used for forged products. |

| 2117 | 2117 | After solid solution heat treatment, it is used as a hinge material and is an alloy that delays the rate of the effect at room temperature. |

| 2018 2218 | 2018 2218 | Alloy for forging. It has good forging properties and high high-temperature strength, so it is used for forging products that require heat resistance. Corrosion resistance is not good. |

| 2618 | 2618 | Alloy for forging. Excellent high temperature strength but poor corrosion resistance. |

| 2219 | 2219 | High strength, good low and high temperature properties, excellent solubility, but poor corrosion resistance. |

| 2025 | 2025 | Alloy for forging. Good forging properties and high strength, but corrosion resistance is not good. |

| 2N01 | Alloy for forging. Heat-resistant and strong, but not good at resisting corrosion. | |

Hardness and Corrosion Resistance

The higher hardness of Series 2 aluminum alloys is due to the addition of copper elements and the strengthening effect of the solid solution. This increase in hardness makes Series 2 aluminum alloys excellent for parts subjected to higher loads, such as structural parts for aircraft. However, a decrease in corrosion resistance often accompanies the increase in hardness, and Series 2 aluminum alloys are not as corrosion resistant as Series 1 or 3 aluminum alloys.

In terms of corrosion resistance, Series 2 aluminum alloys are susceptible to intergranular corrosion, especially during welding or heat treatment. In order to improve corrosion resistance, Series 2 aluminum alloys require special protective measures during processing and use, such as special welding techniques or appropriate heat treatment.

Despite the limitations in corrosion resistance, Series 2 aluminum alloys offer irreplaceable advantages in specific applications. For example, alloy 2024 is widely used in aerospace components such as wing beams and engine pistons for aircraft due to its high strength and good machinability. In addition, Series 2 aluminum alloys are also commonly used in the manufacture of high-speed trains, automotive parts and other industrial products that require high strength and good machinability.

Series 3 Aluminum Alloys: Properties and Applications

Chemical Composition and Physical Properties

Series 3 aluminum alloys have manganese as the main alloying element, and the content of manganese in their chemical composition is generally between 1.0% and 1.5%. Representative grades include 3003, 3105, etc. The density of 3-series aluminum alloys is about 2.7 g/cm³, similar to that of 1-series aluminum alloys, but with higher strength and σb values up to 200-300 MPa.

The physical properties of 3-series aluminum alloys are mainly reflected in their good rust resistance and processability. Due to the addition of manganese, the corrosion resistance of the alloy has been significantly improved, while maintaining the lightweight characteristics of the aluminum material. 3 series aluminum alloy’s electrical and thermal conductivity is not as good as that of the 1 series, but it still maintains the excellent characteristics of the aluminum material, and the electrical conductivity can reach about 30% of the international annealed copper standard conductivity.

3 series aluminum alloy processing performance is good, can be rolled, extruded and other methods to make plates, tubes, bars, etc.. In addition, the 3 series aluminum alloy welding performance is also excellent, suitable for a variety of welding processes.

| Alloy Series | Alloy Number | Material Characteristics Summary | |

| JIS | A.A | ||

| 3000 Series | 3003 3203 | 3003 3203 | The strength is about 10% higher than that of 1100, and the molding, solubility and corrosion resistance are good. |

| 3004 3104 | 3004 3104 | Higher strength than 3003, superior moldability, and good corrosion resistance. | |

| 3005 | 3005 | The strength is about 20% higher than 3003, and the corrosion resistance is also better. | |

| 3105 | 3105 | The strength is slightly higher than 3003, and other properties are similar to 3003. | |

Rust protection and application areas

The rust protection of Series 3 aluminum alloys is mainly due to the addition of manganese, which gives the alloys better corrosion resistance in general environments. In wet or chemically corrosive environments, Series 3 aluminum alloys have better corrosion resistance than Series 1 and 2, but protective measures are still required to avoid corrosion.

Series 3 aluminum alloys are used in a wide range of applications, including architectural decoration, chemical equipment, food processing equipment, shipbuilding, and more. For example, 3003 alloy is commonly used in the manufacture of beverage cans, food packaging materials, and architectural decorative panels due to its good rust resistance and processability. In addition, Series 3 aluminum alloys are also suitable for the manufacture of tanks and cans for liquid products, construction processing parts, construction tools, and various lamp parts.

In the automotive industry, Series 3 aluminum alloys are used to manufacture body parts, radiators, etc., due to their light weight and good machinability. In the aerospace industry, Series 3 aluminum alloys are also used to manufacture non-critical structural components such as fuel guides.

The rust-proof function of 3 series aluminum alloys and the diversity of application areas make them one of the indispensable materials in industrial production. With the development of technology and the increase in application demand, the processing technology and application range of 3 series aluminum alloy will be further expanded and optimized.

Series 4 Aluminum Alloy Characteristics and Applications

Chemical Composition and Physical Properties

Series 4 aluminum alloys use silicon as the main alloying element, and the content of silicon in their chemical composition is usually between 4.5% and 13.5%, with representative grades including 4032, 4047, etc. The density of Series 4 aluminum alloys is about 2.7 g/cm³, which is similar to that of Series 1 and Series 3, but the strength and hardness are much higher, with σb values of up to 200-350 MPa. MPa.

The physical properties of Series 4 aluminum alloys are mainly reflected in their high melting points and good welding properties. The addition of silicon significantly increases the melting point of the alloy, resulting in better thermal stability during welding. In addition, the thermal and electrical conductivity of Series 4 aluminum alloys is not as good as Series 1, but still maintains the relatively good characteristics of aluminum materials.

The 4 series aluminum alloy processing performance is good, which can be made by hot rolling, cold rolling, extrusion and other methods to make a variety of shapes of materials. Due to the addition of silicon, the wear resistance and hardness of Series 4 aluminum alloys have also been improved, making them suitable for the manufacture of parts subject to wear and tear.

| Alloy Series | Alloy Number | Material Characteristics Summary | |

| JIS | A.A | ||

| 4000 Series | 4032 | 4032 | Good heat resistance, good fur resistance, small coefficient of thermal expansion. |

| 4043 | 4043 | Good flow, less solidification shrinkage, natural gray color with sulfuric acid anodic oxidation treatment. | |

Solidification Characteristics and Heat Resistance

The solidification characteristics and heat resistance of 4-series aluminum alloys are closely related to their chemical composition. The addition of silicon not only raises the melting point of the alloy but also improves its stability at high temperatures. During solidification, silicon tends to be enriched at grain boundaries, which helps to refine the grains and improve the thermal stability and heat resistance of the material.

The heat resistance of Series 4 aluminum alloys is mainly due to their ability to resist oxidation and corrosion at high temperatures. In a high temperature environment, the oxide film formed on the surface of 4 series aluminum alloys protects the material from further oxidation and corrosion, giving it a long service life in high temperature applications.

The application areas of 4-series aluminum alloys are mainly focused on applications that require good welding performance and high temperature stability. For example, in the automotive industry, 4-series aluminum alloys are used to manufacture high-temperature components such as engine parts and exhaust systems. In addition, 4-series aluminum alloys are also suitable for the manufacture of heat sinks for electrical equipment, pipes and containers for chemical equipment, and so on.

With the development of industrial technology, the application of 4 series aluminum alloy in new energy, aerospace and other high-end fields is also expanding. Its excellent heat resistance and welding performance make it an indispensable key material in these fields.

Series 5 Aluminum Alloy Characteristics and Applications

Chemical Composition and Physical Properties

Series 5 aluminum alloys are mainly characterized by their magnesium content, which is usually between 3% and 5% in their chemical composition, and representative grades include 5005, 5052, 5083, etc. Series 5 aluminum alloys have a low density, usually in the range of 2.68-2.80 g/cm³, which makes them ideal for lightweight designs. Also, Series 5 aluminum alloys have a low melting point, which facilitates casting and welding.

The physical properties of Series 5 aluminum alloys include good formability, weldability and moderate strength. The addition of magnesium significantly increases the strength of the alloy while maintaining a low density, making Series 5 aluminum alloys very popular for structural applications. In addition, Series 5 aluminum alloys have good corrosion resistance, especially in marine environments, thanks to the modifying effect of magnesium on corrosion products.

The electrical and thermal conductivity of Series 5 aluminum alloys is not as good as that of Series 1 aluminum alloys, but still maintains the relatively good characteristics of aluminum materials, with electrical conductivity reaching approximately 35% of the international standard conductivity for annealed copper. In addition, the heat treatment effect of 5 series aluminum alloy is not as significant as that of 2 series and 7 series, but its mechanical properties can be further improved through appropriate heat treatment.

| Alloy Series | Alloy Number | Material Characteristics Summary | |

| JIS | A.A | ||

| 5000 Series | 5005 – | 5005 5050 | Strength is the same as 3003, good processability, solubility, corrosion resistance, good modification process after anodic oxidation, and the color is compatible with 6063 extrusion material. |

| 5052 | 5052 | It is the most representative alloy of medium strength, with good corrosion resistance, solubility and formability, especially high fatigue strength and good seawater resistance. | |

| 5652 | 5652 | Alloy to limit the impurity element of 5052 and inhibit the separation of hydrogen peroxide, other characteristics are the same as 5052. | |

| 5154 | 5154 | Strength is about 20% higher than 5052, other properties are the same as 5052. | |

| 5254 | 5254 | An alloy that restricts the impurity elements of 5154 and inhibits the decomposition of hydrogen peroxide, other properties are the same as those of 5154. | |

| 5454 | 5454 | The strength is about 20% higher than 5052, and its characteristics are more or less the same as those of 5154, but the corrosion resistance is better than that of 5154 in severe environments. | |

| 5056 | 5056 | Corrosion resistance is superior to cutting and work surface modification, anodic oxidation treatment and its dyeing is good. | |

| 5082 | 5082 | Strength is similar to 5083, good molding and corrosion resistance. | |

| 5182 | 5182 | The strength is about 5% higher than 5082, and other characteristics are the same as 5082. | |

| 5083 | 5083 | Alloys for solvent-bonded structures. It is the strongest corrosion-resistant alloy among practical non-heat-treated alloys and is suitable for solvent-bonded structures. Good seawater resistance and low temperature characteristics. | |

| 5086 | 5086 | The strength is higher than 5154, and it is a non-heat-treatable alloy with good seawater resistance. | |

| 5N01 | The strength is the same as 3003, and the anodic oxidizing treatment can have very high brightness after the light treatment. Good molding and corrosion resistance. | ||

| 5N02 | Alloy for hinges, good seawater resistance. | ||

Lightweight and High Strength Properties

The lightweight properties of 5-series aluminum alloys allow for a wide range of applications in the transportation sector, especially in automotive and shipbuilding. Due to their low density and good mechanical properties, Series 5 aluminum alloys are used in vehicle body structures, engine components and ship hull structures to reduce weight and improve fuel efficiency.

High-strength properties make Series 5 aluminum alloys also useful in applications subject to higher loads. For example, alloy 5052 is widely used in the manufacture of ships, vehicle structural components, pressure vessels, etc., due to its good weldability and moderate strength. Alloy 5083, on the other hand, is commonly used to make structural parts for marine applications and components for transportation equipment due to its higher strength and good corrosion resistance.

The lightweight and high-strength characteristics of 5-series aluminum alloys, combined with their good machinability and weldability, make them one of the indispensable materials in modern industry. With the increased demand for lightweighting and environmental protection, the application areas of 5-series aluminum alloys will continue to expand, especially in the areas of automotive lightweighting, aerospace and transportation.

Series 6 Aluminum Alloys Characteristics and Applications

Chemical Composition and Physical Properties

Series 6 aluminum alloys, with their magnesium and silicon as the main alloying elements, are heat-treatable reinforced aluminum alloys with excellent machinability and weldability. Representative grades include 6061, 6063, 6082, etc. The chemical composition of Series 6 aluminum alloys usually contains 0.5% to 1.0% magnesium and 0.2% to 0.6% silicon, and may also contain trace amounts of copper, manganese, chromium, and other elements to improve alloy performance.

The density of Series 6 aluminum alloys is about 2.7 g/cm³, which is similar to that of Series 1 and Series 3, but its strength and hardness are higher, with σb values up to 240-280 MPa. Appropriate heat treatments, such as solid solution treatment and artificial aging, can significantly improve its mechanical properties. 6 Series aluminum alloys have electrical and thermal conductivity that is not as good as that of Series 1, but they still maintain the relatively good properties of aluminum materials.

| Alloy Series | Alloy Number | Material Characteristics Summary | |

| JIS | A.A | ||

| 6000 Series | 6061 | 6061 | Heat-treated corrosion-resistant alloy. T6 has a very high endurance value, but the strength of the solvent interface is low, so it is used for screws and hinges. |

| 6N01 | Medium-strength extrusion alloy, 6061 and 6063 of the middle of the strength, extrusion sex stamping quenching are good, can be used for complex shapes of large-scale thin meat-shaped material, corrosion resistance sex, solubility are good. | ||

| 6063 | 6063 | Typical extrusion alloy, lower strength than 6061, good extrudability, can be used for complex cross-section shape of the shape of the material, corrosion resistance and surface treatment are good. | |

| 6101 | 6101 | High strength conductive material. 55% IACS guarantee. | |

| 6151 | 6151 | It has excellent forging processability, corrosion resistance and surface treatment, and is suitable for complex forged products. | |

| 6262 | Corrosion-resistant fast-cutting alloy, corrosion resistance and surface treatment is better than 2011, its strength is the same as 6061. | ||

Machinability and corrosion resistance

The machinability of 6 series aluminum alloys is extremely good, and can be made into plates, tubes, rods, profiles, etc., by various plastic deformation processing methods. Its good machinability is mainly due to the solid solution strengthening effect of the alloying elements magnesium and silicon, as well as the aging strengthening effect obtained by heat treatment.

The corrosion resistance of Series 6 aluminum alloys is also quite good, especially after heat treatment. Series 6 aluminum alloys maintain good stability in natural environments and a wide range of chemical media. In addition, Series 6 aluminum alloys have good surface treatability and can be surface-treated by anodizing, electroplating, and painting to obtain the desired appearance and properties.

Series 6 aluminum alloys are widely used in aerospace, transportation, machinery and equipment, building structures and other fields. For example, 6061 alloy is widely used in the manufacture of aircraft structural parts, automotive parts, bicycle frames, etc., due to its high strength, good toughness and excellent welding performance. 6063 alloy is commonly used in the manufacture of doors, windows, furniture, electrical appliance housings, etc., due to its good machinability and surface treatment.

With the improvement of material performance requirements, the alloy design and processing technology of 6 series aluminum alloys are also developing continuously to meet the demand for high-performance aluminum alloys in different applications.

7 Series Aluminum Alloys Characteristics and Applications

Chemical Composition and Physical Properties

7 Series Aluminum Alloys are known for their ultra-high strength and good machinability, and their chemical compositions contain mainly zinc, magnesium, copper and other elements. Representative grades include 7075 and 7050. The density of this alloy is about 2.8 g/cm³, and its strength can reach a σb value of 500 MPa or more, which is one of the highest strength series in aluminum alloys.

| Alloy Series | Alloy Number | Material Characteristics Summary | |

| JIS | A.A | ||

| 7000 Series | 7072 | 7072 | The electrode potential is low, and it is mainly used for anti-corrosive covering materials, and also for heat sinks of heat exchangers. |

| 7075 | 7075 | Aluminum alloy with the highest strength of one of the alloys, but the corrosion resistance is not good, and 7072 of the cover skin material can improve its corrosion resistance, but the cost increases. | |

| 7050 | 7050 | Improve the hardenability of 7075 alloy, good resistance to stress corrosion cracking, suitable for thick plates, forging products. | |

| 7N01 | Alloys for bonding structures have high strength, and the strength of the bonded portion can be brought back to a strength close to that of the base material when left at room temperature. Corrosion resistance is also very good. | ||

| 7003 | 7003 | Extruded alloy for dissolving structure, slightly lower strength than 7N01, but good extrudability, can be used as a thin meat of the large-scale shape of the material, other characteristics are generally the same as 7N01. | |

Superhard Properties and Aerospace Applications

The superhard properties of 7-series aluminum alloys are mainly due to the solid solution strengthening and aging-strengthening effects of their alloying elements. After solid solution treatment, alloying elements such as zinc and magnesium form a solid solution in the aluminum matrix, which significantly increases the strength of the material. Subsequent aging treatments further increase the yield and tensile strength of the material through a precipitation strengthening mechanism.

Series 7 aluminum alloys are used in a wide range of aerospace applications, mainly in the manufacture of aircraft structural components such as wing girders, fuselage frames and landing gear. These components require extremely high strength and good toughness to withstand the various loads during takeoff and flight. The high strength and good machinability of 7-series aluminum alloys make them the material of choice for the aerospace industry.

Series 8 Aluminum Alloys: Properties and Applications

Chemical Composition and Physical Properties

Series 8 Aluminum Alloys are a diverse family of alloys that encompasses alloying systems other than those in the Series 1 through 7 families. These alloys often contain special elements such as lithium and iron that give them unique properties, with the representative grade being 8011.

The chemical composition of 8-series aluminum alloys is varied, and the properties of the alloys can be tailored to meet the needs of the application. For example, lithium-containing aluminum alloys have lower density and higher modulus of elasticity, while iron-containing aluminum alloys have good heat and oxidation resistance.

Areas of application

Due to their special characteristics, Series 8 aluminum alloys are not as widely used as the other series, but they play an important role in specific applications. 8 series aluminum alloys are commonly used to make aluminum foils for food packaging, pharmaceutical packaging and other industrial uses. Series 8 aluminum alloys may be selected for industrial applications where special properties are required, such as high-temperature environments or applications with special chemical properties.

The effect of adding different alloying elements on properties:

| Alloying Element | Additions % | Compounds formed in alloys | Effect on alloy properties |

| Mg | 0.2-0.6 | Mg2Si, Al3Mg2 | Enables alloys to be strengthened by heat treatment |

| Cu | 1.0-5.0 | CuAl2 | Strengthening alloys, so that the alloy does not deteriorate with high strength, mostly used in die-casting alloys |

| Ti | 0.1-0.3 | Al3Ti | Refinement of grain, improve mechanical properties |

| Rare Earth Element (chemistry) | 1-1.5 | Refinement of grain size and improvement of thermal strength | |

| Mn | Appropriate Amount | AI10Mn2Si | Mitigating the harmful effects of Fe |

| Zr | 0.1-0.4 | AI3Zr | Refinement of grains |

| Co | 0.5-1.0 | AI9Co2 | Reduces the harmful effects of Fe and improves heat resistance. |