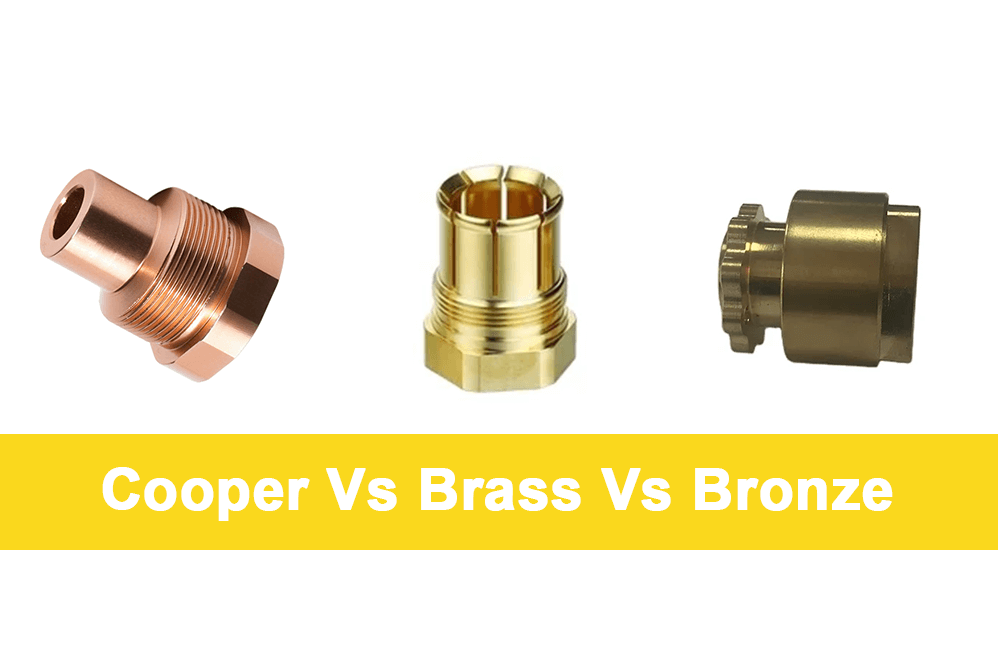

I. Differences Between Brass, Copper, and Bronze

Copper, brass, and bronze are three of the most widely used copper-based metals in manufacturing, prototyping, and various industries. Although they all belong to the same family, each has unique properties, compositions, and ideal applications. Understanding their differences will help you select the best material for your project.

Table of Contents

II. Basic Overview of Brass

Brass is an alloy of copper and zinc. Adjusting the zinc content allows manufacturers to tailor its strength and ductility. The zinc content in industrial brass is usually below 45% to prevent brittleness.

Types of Brass:

- Ordinary Brass

- Single-phase brass (α-brass): Zinc content <39%. Excellent plasticity, good for hot and cold forming.Dual-phase brass (α+β brass): Zinc content >39%. Higher strength but lower ductility, suitable for hot working only.Example grades:

- H90, H80: Single-phase brass, golden color, used for decorative plating, medals.H68, H59: Dual-phase brass, used in structural parts like bolts, nuts, washers, and springs.

- Single-phase brass (α-brass): Zinc content <39%. Excellent plasticity, good for hot and cold forming.Dual-phase brass (α+β brass): Zinc content >39%. Higher strength but lower ductility, suitable for hot working only.Example grades:

- Special Brass

Special brass includes additional elements like lead, tin, or aluminum to improve tensile strength and workability.- Example: HPb59-1 — 59% copper with 1% lead (remaining zinc), lead boosts machinability.

III. Basic Overview of Copper

Pure Copper

Copper is a rose-red metal, turning purplish when an oxide film forms on its surface. Hence, it is often called “red copper” or “electrolytic copper.” It has a density of 8–9 g/cm³ and a melting point of 1083°C.

Copper has exceptional electrical conductivity, second only to silver, and excellent thermal conductivity. Makes it a go-to material for wires, cables, electrical brushes, and magnetic instruments requiring minimal magnetic interference, such as compasses and aviation gauges.

It is also highly ductile and malleable, easily formed into tubes, rods, wires, strips, sheets, and foils through hot or cold processing.

Classifications:

In China, wrought copper is categorized into four types:

- Ordinary red copper (T1, T2, T3, T4)

- Oxygen-free copper (TU1, TU2, high-purity or vacuum oxygen-free copper)

- Deoxidized copper (TUP, TUMn)

- Specialty copper with minor alloying elements (arsenic copper, tellurium copper, silver copper)

Corrosion Resistance and Workability:

Copper resists corrosion in air, seawater, some non-oxidizing acids, alkalis, salts, and organic acids like acetic and citric acid — making it popular in the chemical industry. It is easy to weld and form into diverse semi-finished and finished parts.

Note on Impurities:

Trace elements like titanium, phosphorus, iron, and silicon can greatly reduce conductivity. Cadmium and zinc have minimal impact. Elements like oxygen, sulfur, selenium, and tellurium can form brittle compounds and lower ductility.

In a reducing atmosphere, copper can suffer from “hydrogen disease,” where hydrogen reacts with cuprous oxide at grain boundaries, producing high-pressure steam or CO₂ gas that cracks the copper.

Bismuth and lead create low-melting eutectics, causing hot brittleness; bismuth films at grain boundaries also cause cold brittleness. Phosphorus reduces conductivity but enhances molten fluidity and weldability. Small amounts of lead, tellurium, or sulfur improve machinability.

IV. Basic Overview of Bronze

What is Bronze?

Originally, bronze referred to copper-tin alloys, named for their blue-gray color. Today, bronze also includes copper alloys with elements like lead, zinc, phosphorus, or aluminum. Because tin is scarce, many industrial bronzes are tin-free and offer tailored properties at lower costs.

Bronze can be divided into wrought and cast products.

Categories:

- Tin Bronze (Copper-Tin Alloy)

- Tin content <5–6%: α solid solution forms, increasing ductility.

- Tin content >5–6%: A Cu₃₁Sn₈-based solid solution appears, lowering tensile strength. Tin bronze typically contains 3–14% tin.

- Processing:

- <5% tin: suitable for cold working

- 5–7% tin: suitable for hot working

- > 10% tin: suitable for casting

- Advantages: Excellent corrosion resistance (forms a protective tin oxide layer), good wear resistance, anti-magnetic, good toughness at low temperatures.

- Disadvantages: Wide solidification range and poor fluidity; suitable for casting complex shapes but not high-density or airtight castings.

- Common grades:

- Wrought: QSn4-3, QSn6.5-0.1 (plates, strips, rods, tubes, elastic parts, bearings)

- Cast: ZQSn10-1, ZQSn6-6-3 (sliding bearings, gears)

- Special Bronze (Non-Tin Bronze)

Tin may be replaced by aluminum, lead, or other elements to achieve specific properties. Many special bronzes offer higher strength, wear resistance, and corrosion resistance than tin bronze.- Examples: Aluminum bronze (QAl7, QAl5), Lead bronze (ZQPb30)

- White Copper (Cu-Ni Alloy)

Copper-nickel alloys appear silvery white. The nickel content is typically 10%, 15%, or 20% — higher nickel means a whiter color.- Ordinary white copper: binary copper-nickel alloy.

- Complex white copper: contains additional elements like manganese, iron, zinc, or aluminum.

Nickel enhances strength, corrosion resistance, and special electrical or thermal properties. Industrial white copper is divided into structural and electrical grades.

V. How to Identify Brass, Bronze, and Copper

| Property | Brass | Bronze | Copper |

| Key Feature | Zinc increases strength & ductility | Tin increases corrosion resistance | Excellent electrical & thermal conductivity |

| Main Elements | Copper + Zinc | Copper + Tin | 99.3% Copper |

| Color | Yellow to reddish-yellow | Dark gold / reddish-brown | Purplish-red |

| Cost | Cheapest | Moderate | Most expensive |

| Melting Point | 900°C – 1000°C | 950°C – 1050°C | 1084°C |

| Hardness (HB) | 55 – 73 | 40 – 420 (stronger but more brittle) | 89 |

| Thermal Conductivity | 120 W/m·K | 24 W/m·K | 397 W/m·K |

| Fatigue Strength | 22 – 360 MPa | 90 – 352 MPa | 200 – 375 MPa |

| Shear Strength | 35,000 psi – 48,000 psi | 35,000 psi – 47,000 psi | 25,000 psi |

| History | Used since ~500 BC | Used since ~3500 BC | Used since ~3000 BC |

Ⅵ. Bronze vs Brass vs Copper: Pros and Cons Comparison Table

| Property | Brass | Bronze | Copper |

| Pros | – Easy to machine and cast – Good strength and ductility – Attractive golden color for decorative uses – Cost-effective | – Excellent corrosion resistance, especially in marine environments – High strength and wear resistance – Good for bearings, bushings, and sculptures – Stronger than brass in many cases | – Highest electrical and thermal conductivity – Excellent ductility and workability – Corrosion resistant in many environments – Essential for electrical applications |

| Cons | – Susceptible to dezincification in some conditions (loss of zinc) – Less corrosion resistant than bronze – Not as strong as bronze for heavy-duty applications | – Typically more expensive than brass – Can be more brittle (especially with higher tin content) – Harder to machine than brass | – Soft compared to brass and bronze – Expensive due to high purity – Can suffer from hydrogen embrittlement during processing |

Ⅶ. Bronze vs Brass vs Copper: Selecting the Right Material for Your Projects

Choosing between bronze, brass, and copper depends largely on the specific requirements of your project, including factors like strength, corrosion resistance, conductivity, cost, and appearance. Here’s a guide to help you make an informed decision:

1. Consider the Application Environment

- Bronze is an excellent choice for applications exposed to harsh environments, especially marine or chemically corrosive settings, due to its superior corrosion resistance and wear properties. Ideal for bearings, bushings, and outdoor sculptures.

- Brass offers good corrosion resistance and is favored for decorative applications, musical instruments, and plumbing fittings. It’s easier to machine and provides a bright, golden finish.

- Copper shines in electrical and thermal applications where conductivity is critical, such as wiring, heat exchangers, and electronic components.

2. Evaluate Mechanical Properties

- If strength and durability are priorities, bronze generally outperforms brass and copper, especially in wear resistance.

- For ductility and ease of fabrication, brass and copper are preferable, with brass offering better machinability and copper offering excellent malleability.

3. Budget Considerations

- Brass tends to be the most cost-effective option among the three.

- Bronze is usually moderately priced but provides added performance benefits.

- Copper is typically the most expensive due to its high purity and specialized uses.

4. Aesthetic Preferences

- For a warm, golden look, brass is the go-to metal.

- Bronze offers a darker, antique appearance that patina beautifully over time.

- Copper has a distinct reddish-purple hue and develops a unique green patina with age, often sought after in architectural designs.

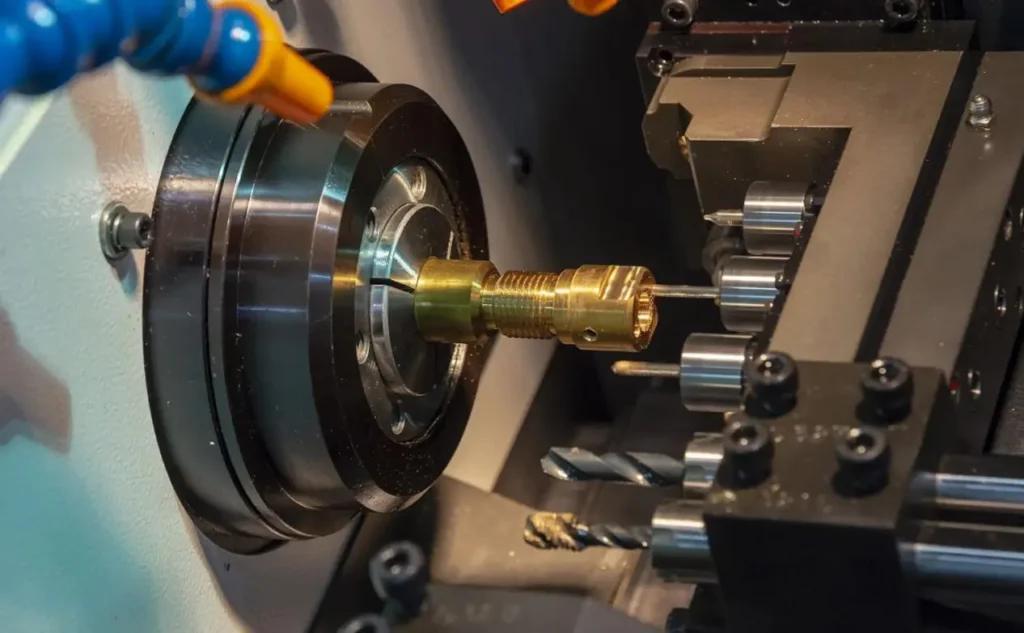

Ⅷ. Common Machining Challenges and Tips for Brass, Bronze, and Copper

When working with brass, bronze, and copper in machining or prototyping projects, understanding their unique behaviors and challenges is key to achieving precision and efficiency. Below are common machining issues and practical tips for each metal:

1. Copper

Challenges:

- Copper is soft and ductile, causing it to “gum up” or stick to cutting tools.

- Its excellent thermal conductivity can lead to rapid heat transfer, potentially distorting thin parts.

- Pure copper is prone to work hardening, which may require frequent tool adjustments.

Tips:

- Use sharp, well-lubricated cutting tools to minimize material sticking.

- Use high spindle speeds with light cuts to reduce tool pressure.

- Regularly inspect and dress cutting edges to maintain tool sharpness.

2. Brass

Challenges:

- Brass can experience “dezincification” in some environments, which weakens the metal, though this is more a corrosion issue than machining.

- While generally easy to machine, lead-free brass grades can be tougher and more prone to tool wear.

- Some brass alloys may produce burrs during cutting.

Tips:

- Use sharp cutting tools with appropriate coatings to reduce wear.

- Maintain proper coolant/lubrication to avoid overheating and ensure smooth finishes.

- For lead-free brass, reduce feed rates and increase cutting speed slightly for cleaner cuts.

3. Bronze

Challenges:

- Bronze is harder and more abrasive than brass, which can lead to faster tool wear.

- Certain bronze alloys are brittle, increasing the risk of cracking or chipping during machining.

- Poor thermal conductivity compared to copper can cause heat buildup at the cutting edge.

Tips:

- Use carbide or coated tools designed for abrasive materials.

- Employ ample coolant and slower feed rates to manage heat.

- Pre-heat or stress-relieve the workpiece if machining thick sections to reduce brittleness.

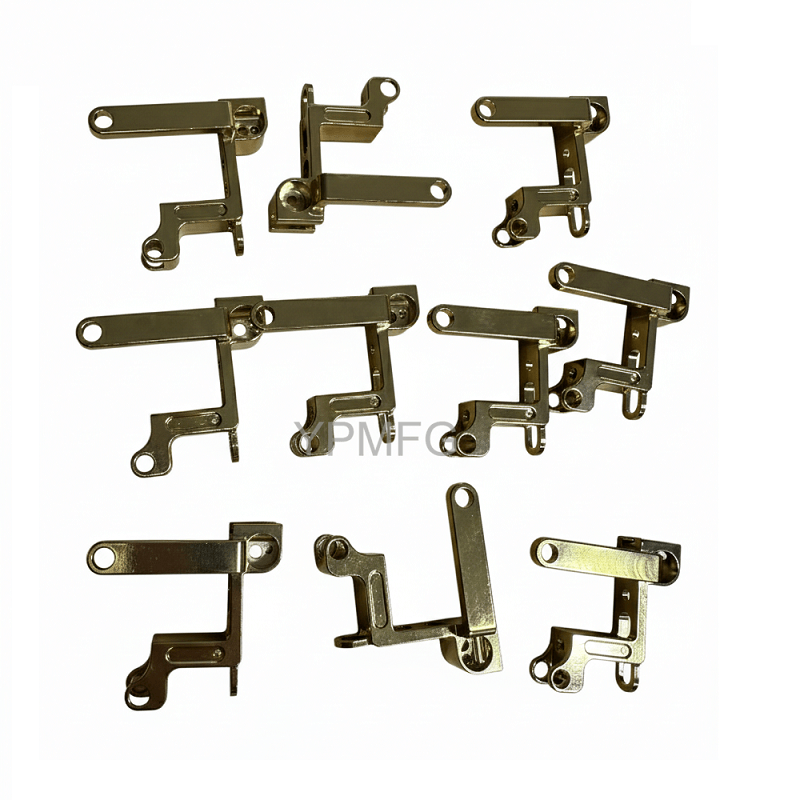

Ⅸ. Choose YP-MFG for Your Metal Machining and Prototyping Projects

When it comes to precision metal machining and prototyping, choosing the right partner is crucial. At YP-MFG, we offer high-quality machining services for brass, bronze, copper, and other metals. Our experienced team understands the unique properties of each material and uses advanced CNC equipment to deliver complex prototypes and production parts with tight tolerances and excellent finishes. From design consultation to rapid prototyping, we ensure fast turnaround, strict quality control, competitive pricing, and dedicated customer support—helping you bring your ideas to life efficiently and cost-effectively.

Ⅹ. Conclusion

Copper, brass, and bronze each have unique properties that make them indispensable in modern manufacturing. Knowing their differences enables better design decisions, optimizes performance, and controls costs. Choosing the right supplier ensures your metal components meet high standards from design to final production.

Ⅺ. FAQs

Q1: Is brass stronger than copper?

A: Yes, adding zinc to copper increases its strength and hardness.

Q2: Is bronze more corrosion-resistant than brass?

A: Generally, yes. Bronze, especially tin bronze, offers superior corrosion resistance in marine and harsh environments.

Q3: Can copper be used instead of brass or bronze?

A: It depends on your requirements. Copper has excellent conductivity but lower strength than brass or bronze.

Q4: Which is more machinable, brass or bronze?

A: Brass typically has better machinability, especially leaded brass grades.

Q5: How do I choose the right alloy?

A: Consider strength, corrosion resistance, conductivity, appearance, and cost. Contact us for professional material selection advice!