# Cnc Machining On-Demand Production for

Robotic Industry

- Tolerances up to +/- 0.003 mm

- Engineering Support, High Quality

- ISO 9001:2015 Certified

- Fast Lead Time

Why Manufacture Robtic Parts With YP-MFG?

High-precision machining services for the robotics industry. We offer on-demand production of custom parts, rapid prototyping, and small to large batch manufacturing with tight tolerances and fast turnaround times—ideal for robotic arms, actuators, brackets, and automation components.

ISO Certificate

With our ISO9001 certified production process, combined with expert machining experience and advanced CNC machines, we can ensure your robotic parts are manufactured correctly and delivered on time every time.

Short Lead Time

From prototype to production, from 1 to 10,000 pieces, we offer fast CNC machining for your custom metal and plastic parts with delivery in as fast as 3 days.

Engineering Support

Senior designers provide design and processing suggestions based on processing drawings and scheme designs to optimize structures and reduce costs.

High Quality Parts

Our custom manufacturing for robotics delivers parts that meet precision requirements. Our manufacture robotics parts with tolerances up to +/- 0.003 mm. After passing high quality inspection, the shipment can be confirmed.

Wordwide Customers

We provide an exceptional global service with a large and rapidly growing client base. Our clients are located all over the world and come from a wide range of industries, from independent inventors or designers to large industrial, robotic, medical, automotive and even aerospace companies.

Range of Services

Over 2,000 square-meter CNC machining workshop and more than 70 employees with relevant skills maintain 24/7 operations and can provide a variety of CNC machining services including milling, turning, threading, tapping, EDM and wire cutting, customized surface treatment, etc.

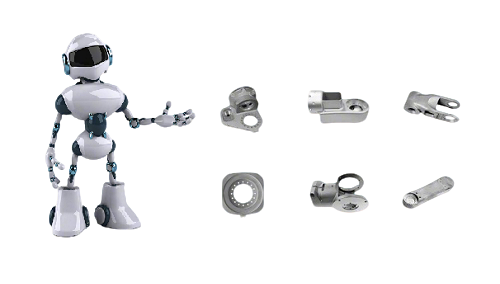

Robtic CNC Machining Products Showcase

- Robotic parts

- Arm components

- Grippers

- Actutors

- Brackets

- Sensors

- Animatronics

- Casings, housings, tubing

- Clamps

- Motors

- End effectors

- Robotics assemblies

- Conveyor belt components

- Controller components

- Manipulator parts

- Automatic control equipment

Our Manufacturing Services

YP-MFG helps meet your needs more effectively, and stay competitive in your industry. Lowered manufacturing costs, increased flexibility.

CNC Machining Service

Casting and Forging

Sheet Metal Fabrication

Aluminum Extrusion

Project Stories of Custom Machining Robtic Parts

Five-axis machining is widely used in the machining of various complex parts due to its high precision and high efficiency. Humanoid robots are highly bionic robots, and their design involves complex mechanical structures, precise motion control, and efficient energy systems. The following is a brief introduction to some of the application cases of five-axis machining in humanoid robots.

Humanoid robot shell and frame processing solutions

In humanoid robot design, the shell and frame must not only have excellent structural strength, but also meet the stringent requirements of lightweight.

YP-MFG uses precision five-axis CNC machining technology to accurately complete complex geometric shapes and internal hollowing designs. Through precision cutting and stable connection, we successfully created a humanoid robot shell and frame that is both light and strong for customers, meeting customer needs and effectively improving the motion performance and structural stability of the whole machine.

Robtic Manufacturing Materials

We offer a vast selection of high-performance materials for the robotic industry. Upload your project to us – we are ready to collaborate and bring your parts for you.

6061, 6082, 7075, A356

Applications: Engine blocks, cylinder heads, brackets, housings, transmission cases

Advantages: Lightweight, corrosion-resistant, good machinability, excellent strength-to-weight ratio

Magnesium alloy is one of the lightest metal structural materials, with a density of only 2/3 of aluminum and 1/4 of steel. The use of magnesium alloy can significantly reduce the weight of robots, improve mobility and endurance, especially in space-constrained or weight-sensitive applications.

Application examples: In drones, wearable exoskeletons and some military robots, magnesium alloys are favored due to their light weight and high strength properties.

Performance characteristics: Magnesium alloys have good damping properties and excellent electromagnetic shielding effects, and are suitable for robot systems that need to reduce vibration and electromagnetic interference.

Titanium alloys have a place in high-end robot manufacturing with their high strength, low density and excellent corrosion resistance. Despite the high cost, titanium alloys provide the necessary material properties for robots that need to operate in extreme environments, such as deep-sea exploration or space operations.

Application examples: In robots that need to withstand extreme temperatures and pressures, such as deep-sea submersibles and spacecraft, the use of titanium alloys can ensure structural integrity and reliability.

Characteristics: Titanium alloys have the same strength as steel but lower density. At the same time, they have excellent corrosion resistance in salt water and chemical media, making them suitable for robots in the marine and chemical industries.

Steel

In the robotics industry, steel serves several critical functions due to its mechanical strength, durability, and resistance to wear and deformation.

Applications: Robot base frames, Joint housings, Arms and links, Linear guide rails, Shafts and axles, Mounting brackets

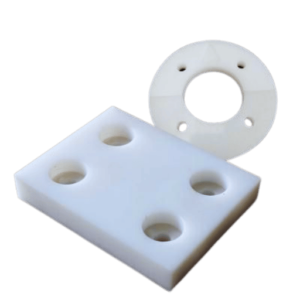

Polyetheretherketone (PEEK) is a special engineering plastic with excellent properties such as high temperature resistance, wear resistance, corrosion resistance, and self-lubrication. It can greatly reduce the weight of the material itself and become a solution to achieve “lightweight”.

Applications: It is suitable for fields with high requirements for lightweight, such as humanoid robots, new energy vehicles, and medical equipment.

ABS plastic: Due to its good mechanical properties and processability, ABS plastic is widely used in robot housings and structural components.

Applications: In parts that require a certain degree of strength and rigidity, such as robot arm housings and tool grippers, ABS plastic can provide sufficient durability.

Characteristics: ABS has good impact resistance and is suitable for applications that are subject to external impact.

Polypropylene (PP): Favored for its chemical resistance and low density, it is suitable for manufacturing battery housings and some protective parts of robots.

Applications: In environments that require lightness and chemical resistance, such as chemical detection robots, the use of polypropylene can provide effective protection.

Characteristics: Polypropylene has good heat resistance and can maintain its performance in the temperature range of -20℃ to 100℃.

Robotics Faqs

Why CNC machining for the robotics industry?

What are common robotic applications of machined parts?

What machining, finishing, and quality processes does YP-MFG offer for robotics?

Do you provide design and engineering support?

How long do I get support?

What happens if a part doesn’t meet your specifications?

Start Your Production Services Now!

Upload Your CAD File → Get Instant Quote → High-Precision Parts in Hand!

Humanoid robot joint and connecting rod manufacturing

In the manufacture of humanoid robots, joints and connecting rod structures have extremely high requirements for precision and strength, especially when facing complex curved structures and multi-angle holes.

YP-MFG uses advanced five-axis CNC machining to accurately complete every detail. Through high-precision cutting and fine grinding, we have successfully created high-strength, high-precision key components to ensure the stability and flexibility of the robot during movement, and provide customers with reliable robot movement solutions.