# Cnc Machining Production for

Automotive

Industry

- Tolerances up to +/- 0.003 mm

- Engineering Support, High Quality

- ISO 9001:2015, ISO 14001 Certified

- Fast Lead Time

Custom Automotive Machined Parts at YP-MFG

YP-MFG offers precision-engineered custom machined parts for the automotive industry, with advanced CNC machining and a skilled engineering team, we manufacture components such as housings, flanges, engine mounts, and transmission parts with exceptional accuracy.

Whether for prototypes, low-volume runs, or mass production, our experienced team ensures every component performs reliably under demanding automotive conditions.

Automotive CNC Machining Products Showcase

- Housing and enclosures

- Assembly line components

- Plastic dash components

- Electric vehicle and battery parts

- E-bike and scooter parts

- Jigs and fixtures

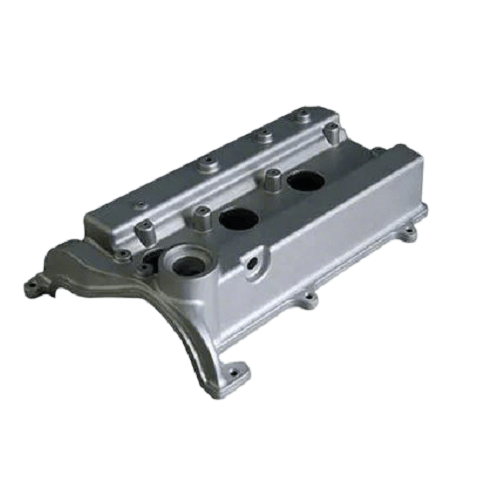

- Engine parts

- Sensor housings

- Connector covers

- Radiator brackets

- Camshaft caps

- Cylinder heads

- Cylinder heads

Our Manufacturing Services

YP-MFG helps meet your needs more effectively, and stay competitive in your industry. Lowered manufacturing costs, increased flexibility.

CNC Machining Service

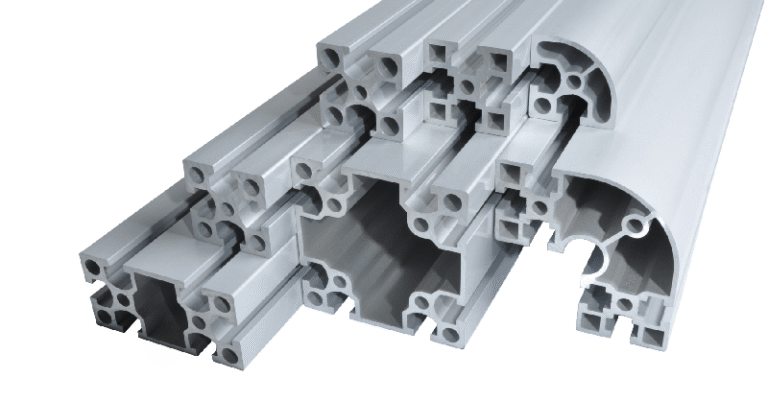

Aluminum Extrusion

Casting and Forging

join the success

Automobile Machining Parts Cases

Automotive Manufacturing Materials

Automotive manufacturing relies on a diverse range of materials, including metals like steel, aluminum, and titanium, as well as engineering plastics and composites to balance strength, weight, cost, and performance.

Aluminum Alloys

6061, 6082, 7075, A356

Applications: Engine blocks, cylinder heads, brackets, housings, transmission cases

Advantages: Lightweight, corrosion-resistant, good machinability, excellent strength-to-weight ratio

Steel

1018, 1045, 4140, 4340, 8620

Applications: Gears, axles, shafts, suspension components, structural supports

Advantages: High strength, toughness, fatigue resistance; good for high-stress parts

Stainless Steel

SS304, SS316, SS410, 17-4PH

Applications: Exhaust components, fasteners, engine sensors, fuel system parts

Advantages: Corrosion resistance, high temperature strength, durability

Cast Iron

Gray Cast Iron, Ductile Iron (e.g., GGG40, GGG50)

Applications: Engine blocks, cylinder liners, brake components

Advantages: Excellent wear resistance, vibration damping, and compressive strength

Copper and Brass

C110 (Copper), C360 (Brass)

Applications: Electrical connectors, heat exchangers, bushings

Advantages: Excellent conductivity, good corrosion resistance, easy to machine

Plastics (Engineering Plastics)

POM (Delrin), Nylon, PTFE, ABS, Polycarbonate

Applications: Bushings, spacers, interior components, fluid connectors

Advantages: Lightweight, corrosion-resistant, good for non-load-bearing parts

Automotive Faqs

What surface finishes are available for CNC automotive parts?

Do CNC machined parts require post-processing?

What quality control measures are used in automotive CNC machining?

Can I request a sample?

How fast can I get my parts?

Do you have automotive manufacturing experience?

#Contact Us

Custom Automotive Machined Part With Easy

Upload your design files for quote pricing, free DFM analysis.

Email: sales@yp-mfg.com

Whatsapp: + 86 137 9493 0097

- Quote Check List:

- 3D and 2D files if available

- Quantity of each part

- Material and grade

- Surface finish if necessary

Request a quote Now!

- All files are secure and confidential.