#On-demand custom gear services

Custom Gear Manufacturing

• ISO 9001, ISO14001 Certificated

• For industries demanding precision and reliability

• Optimize your gear design and help you reach your production goals

YP-MFG Custom Gear Manufacturing

YP-MFG provides custom gear manufacturing services to a wide range of industries. With a diverse product offering, YP-MFG produces all types of gears, including but not limited to helical and spur gears, straight bevel, miter, worm, rack and sprocket gears, as well as splines, sprockets, shafts, assemblies and spare parts. We precision cut gears using machining techniques such as milling, conventional hobbing and climb milling, thread milling, turning, broaching, keyway machining, planing, EDM and flame cutting to meet a wide range of sizes and batch requirements, including complex part combinations and tight tolerances. All products are custom made to our customers' exact specifications, ensuring a perfect fit for their application every time.

Whether you need a custom gear made to order or need some engineering assistance to perfect your design, our team is ready to help, so contact us today.

Play Now

YP-MFG Custom Gear Capabilities

Capabilities

Description

Gear Types

Spur Gears, Helical Gears, Bevel Gears, Worm Gears, Internal Gears, Rack Gears, Spline Gears, Hypoid Gears

Gear Cutting Methods

Milling, Conventional Hobbing, Climb Hobbing, Thread Milling, Turning, Keyseating, Shaping, EDM, Flame Cutting

Materials

Alloy Steel, Carbon Steel, Stainless Steel, Bronze, Cast Iron, Nylon, Custom Materials per Request

Diametral Pitch (Inch)

50 DP – 1 DP

Gear Diameter Range

Up to 1000mm

Heat Treatment

Carburizing, Nitriding, Induction Hardening, Flame Hardening, Quenching & Tempering

Gear Finishing Options

Gear Grinding, Lapping, Honing, Shaving, Shot Peening

Production Volume

Prototype to Mass Production (1 piece to thousands)

Quality Inspection

CMM, Gear Measuring Center, Surface Roughness Tester, Hardness Tester, Ultrasonic Testing, Magnetic Particle Testing

Standards Compliance

ISO, DIN, AGMA, JIS

Additional Services

Assembly, Coating, Custom Packaging, Export Documentation

Custom Gears Applications

-

Automotive:

- Transmission systems, differential gears, power steering units, turbochargers

- Medical:

- Surgical Robots, Minimally Invasive Surgical Gear Drives, Precision Pumps & Drives, Drug Delivery Systems, Pharmaceutical Processing & Packaging Equipment

- Industrial Machinery:

- Gearboxes, conveyors, mixers, compressors, cranes, heavy-duty presses

- Robotics:

- Autonomous Navigation, Motion Control Systems, Precision Drive Mechanisms, precision gear drives, actuator systems, robotic arms, linear drives

- Aerospace:

- Helicopter gearboxes, aircraft flap actuators, landing gear mechanisms

- Energy (Wind, Hydro, Solar):

- Wind turbine gearboxes, hydroelectric drive systems, solar panel actuators

Our Professional Service for Custom Gear

YP- MFG has the engineering and manufacturing expertise to produce precision gears, high speed gears, custom and high speed gearboxes, and other power transmission components for a variety of industries.

Precision Gearing

High Speed Gearing

Custom Gearboxes

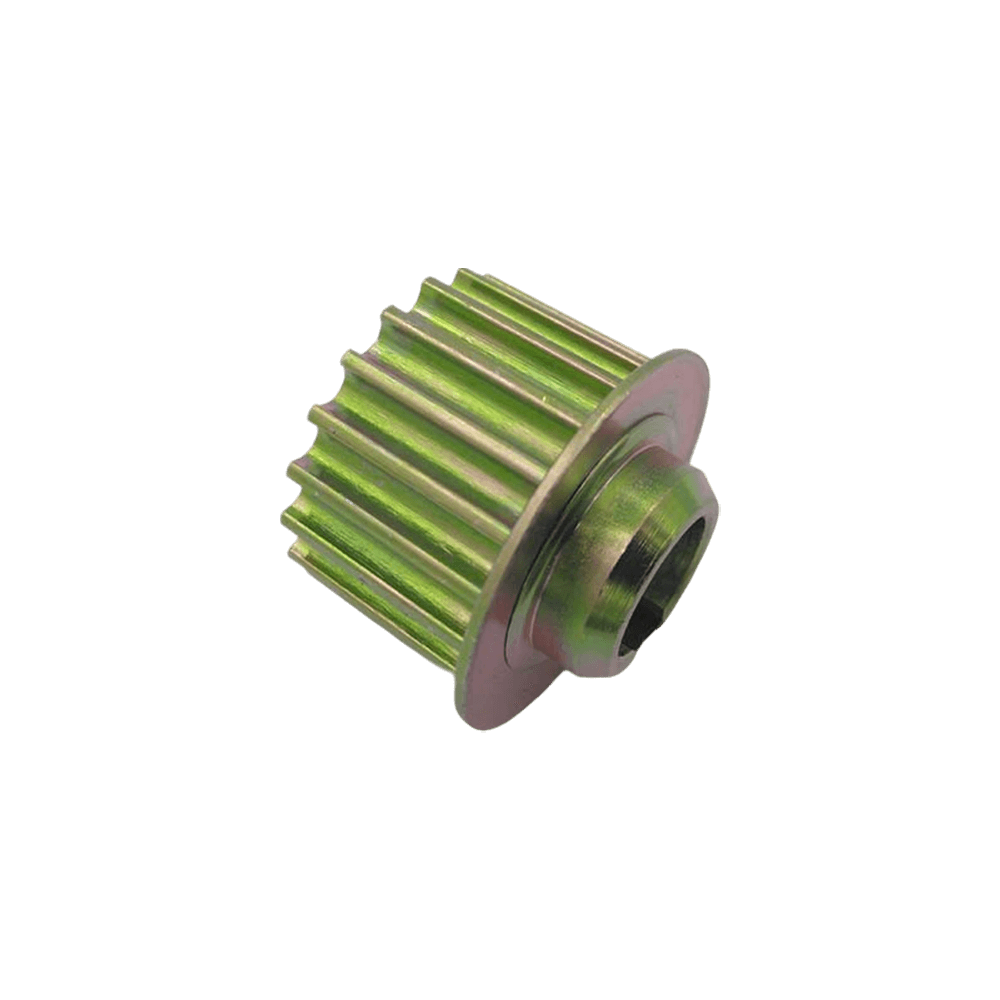

Custom Gear Materials

YP-MFG will work with you to produce custom aluminum extrusions for a variety of projects. Our expert engineers can help you create standard profiles in different sizes and shapes, help you choose the right surface treatment, and more.

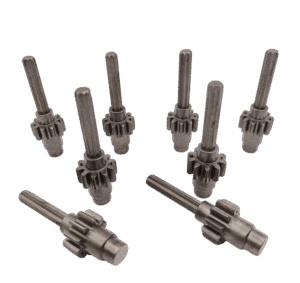

Steel gears are mostly alloy steels, with a few being carbon steels, including quenched and tempered steel, quenched steel, carburized quenched steel, and nitrided steel. Steel has good toughness and impact resistance, and can also be improved through heat treatment or chemical heat treatment to improve its mechanical properties and tooth surface hardness, so it is most suitable for manufacturing gears.

In order to meet the performance requirements of parts, medium carbon steel and low alloy steel can be subjected to various heat treatments to improve their strength and hardness.

Use hardened gears with higher strength and hardness, and extend the service life of gears by optimizing gear material selection and lubrication methods.

Brass gear:

The characteristics of brass are its good strength and durability, as well as the comfort of shaking transmission. In terms of application range, brass gears are suitable for some reels that are high-load and require wheel rigidity.

In terms of processing technology, the process of brass gears is mature and the processing difficulty is relatively small. The raw material price is also cheap and the hardness is relatively soft. Therefore, brass gears are mostly used in some reels that require high strength for fishing and high load or some entry-level reels.

Commonly used cast irons mainly include: gray cast iron, ductile cast iron, malleable cast iron and alloy cast iron. Compared with steel, cast iron has a lower alloy content and better processing performance. The free graphite and porous structure in cast iron make the gears have good wear resistance, low noise and low cost, and can be widely used in various types of gear transmissions.

Due to the good sliding properties of cast iron, cast iron turbines can be used to replace copper alloy turbines in many turbine transmissions with low loads and less harsh working conditions. In short, cast iron is an economical and applicable gear material. Gray cast iron is brittle and has poor impact and wear resistance, but has good resistance to bonding and pitting. It is often used in situations where the work is stable, the speed is low and the power is not high. Ductile iron can partially replace steel to manufacture gears

Aluminum is a good material for low pressure gears and while 7075 isn’t as hard as steel, it’s harder than 6061 so that’s what’s used. And while Al is more costly than steel, it’s much easier to machine. And because it can have a wear coating, it’s actually pretty good material for some applications

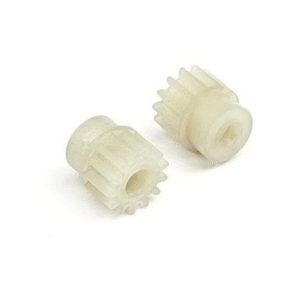

Many non-metallic materials are also increasingly used in the production of gear products, and some of their properties are close to or exceed those of metal materials. The introduction of metals, metal oxides, nanoparticles, reinforced fibers, etc. in the production of high polymer materials can greatly improve the anti-friction and wear performance under various lubrication conditions. In particular, some fields that require oil-free lubrication, high reliability, and low pollution, such as household appliances, medical equipment, food machinery, and textile machinery, are more suitable for gears made of polymer composite materials.

In addition, mass production of plastic or plastic metal gears can effectively reduce production costs and is more suitable for unfavorable environments with pollution and high dust. For high-speed, light-load, and low-precision gear transmissions, in order to reduce noise, non-metallic materials (such as cloth-reinforced bakelite, nylon, etc.) are often used to make small gears.

Custom Gear FAQs

Spur gears, Helical gears, Bevel gears (straight, spiral), Worm gears, Internal gears

We offer a custom gear service, focusing on producing custom and special gears according to your specifications or drawings.

Yes, we offer in-house heat treatment processes, including carburizing, quenching, tempering, and induction hardening. This allows us to better control quality, hardness, and turnaround time.

We work with a variety of materials to suit different performance requirements, including:

Carbon steel (e.g., 1045, 1050)

Alloy steel (e.g., 4140, 4340, 8620)

Stainless steel (e.g., 304, 316, 17-4PH)

Cast iron

Brass, bronze

Aluminum alloys

Engineering plastics (e.g., nylon, pa) for specific applications

Absolutely. Our engineering team can assist you in selecting the most appropriate material based on the application, load requirements, operating environment, and cost considerations.

Several factors influence the cost of gears and parts:

Material type and size

Gear complexity and precision requirements

Quantity (batch size)

Heat treatment and surface finishing needs

Tolerances and inspection standards

In many cases, yes. We can offer expedited production depending on the current workload, material availability, and complexity of the order. Please let us know your required timeline, and we’ll do our best to accommodate.

What information is required to process my custom gear orders quickly and accurately?

To ensure a fast and accurate quotation and manufacturing process, please provide the following:

Detailed drawings or CAD files (with tolerances and key dimensions)

Gear type and specifications (module, pitch, number of teeth, pressure angle, etc.)

Material requirements (if known)

Heat treatment or surface finish requirements

Quantity needed

Delivery deadline or target lead time

#Contact Us

Custom Gears With Easy

Upload your design files for quote pricing, free DFM analysis.

Email: sales@yp-mfg.com

Whatsapp: + 86 137 9493 0097

- Quote Check List:

- 3D and 2D files if available

- Quantity of each part

- Material and grade

- Surface finish if necessary

Request a quote Now!

- All files are secure and confidential.