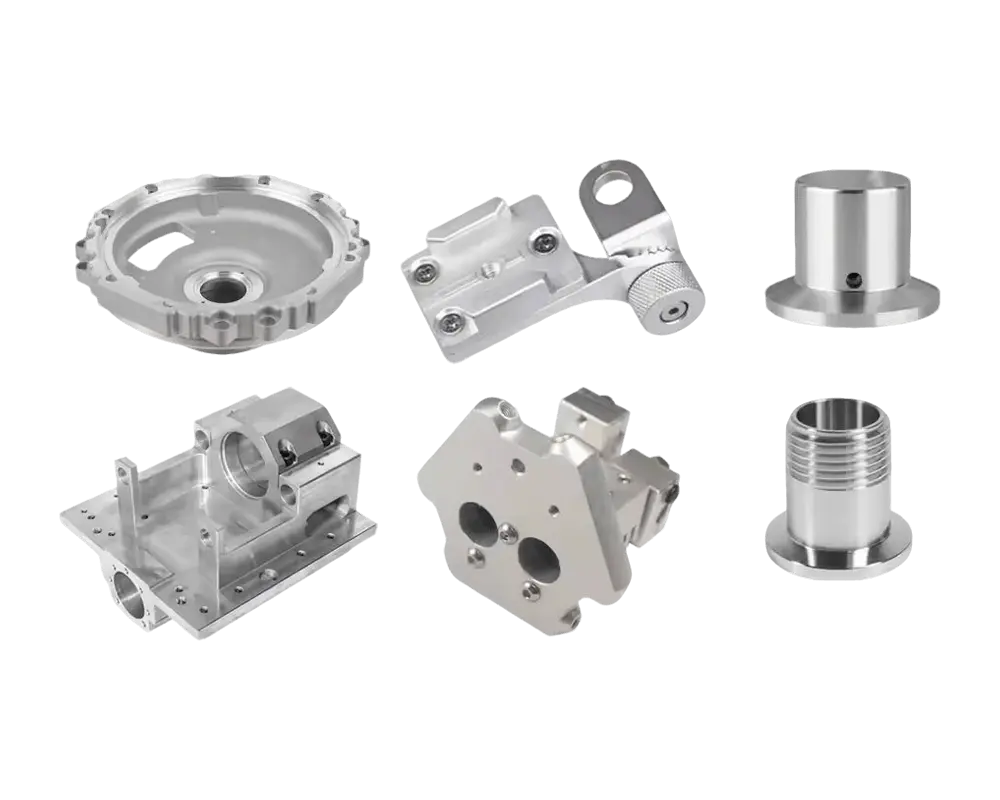

# Fast Delivery, Tight-Tolerance Parts

Custom CNC Machining Services

- ISO 9001:2015 certified

- Instant DFM review

- Low-Volume Manufacturing, No Minimum Order

- Fast Delivery – As Quick as 5 Days

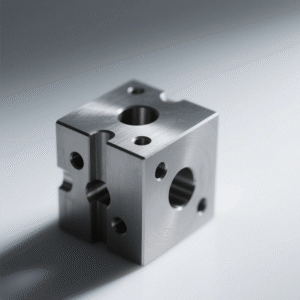

CNC Machining Capabilities

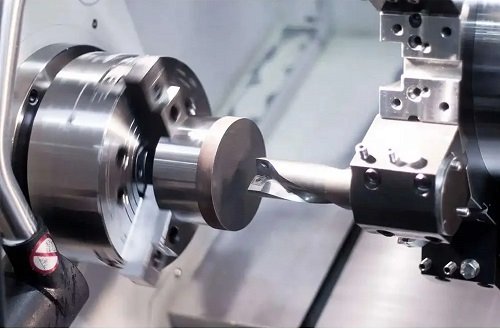

With over 100 advanced machines, like CNC machines, milling machines, and turning machines, we can supply any quantity of metal and plastic parts, from low-volume prototypes to high-volume production.

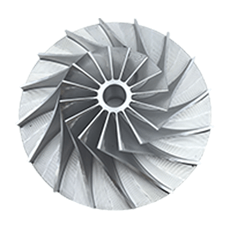

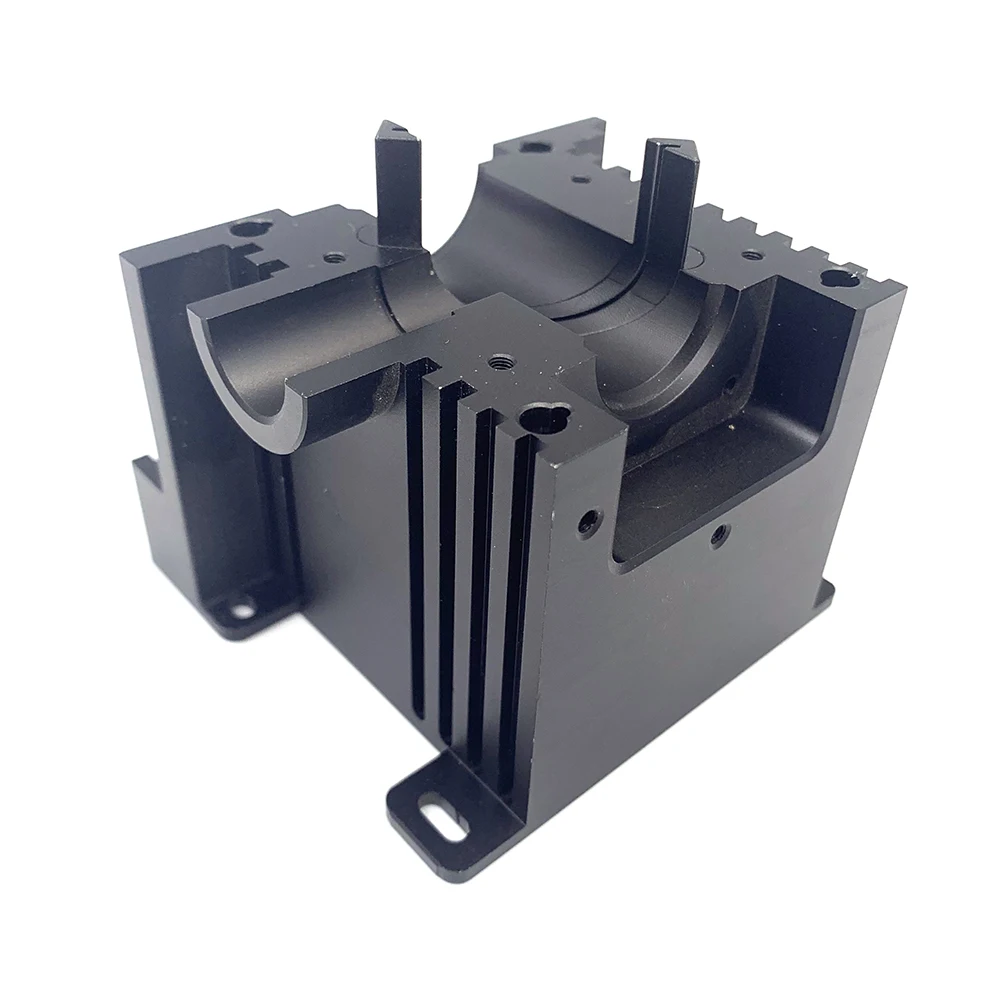

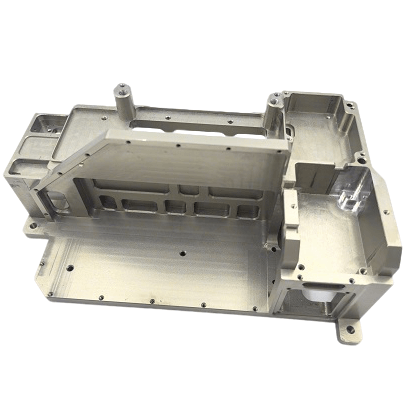

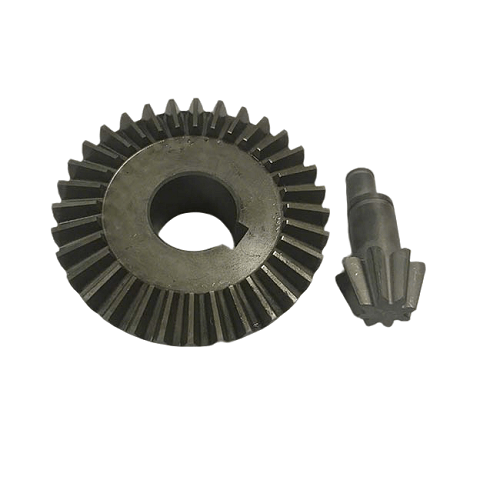

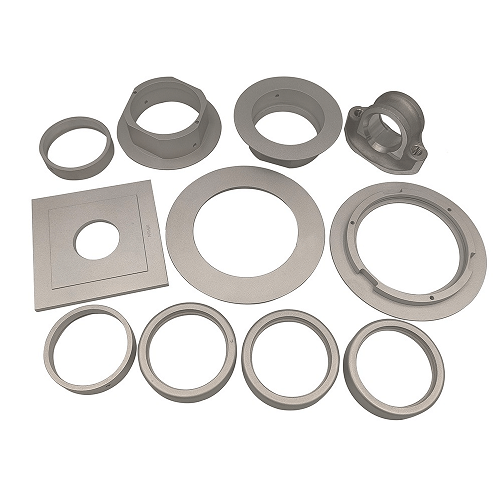

YP-MFG CNC Machined Parts and Equipment Showcase

100+ CNC Machines, operate a full spectrum of multi-axis milling centers, Swiss-type lathes, for high-volume precision. Handle projects from prototypes (48-hour turnaround) to mass production (10,000+ units/month).

5-axis machining for impellers, turbine blades, and micro-molded components with ±0.003mm tolerances. Precision parts for automotive, aerospace, medical, energy, and more.

CNC Machining Tolerances

YP-MFG’s standard tolerance is applied to ISO 2768 (medium) for machined plastic and ISO 2768 (fine) for machined metals. If tighter tolerances are required, a 2D drawing with complete information will be necessary. Our engineering team will communicate with you the critical dimensional tolerances and provide the highest degree of precision possible.

Tolerance for linear dimensions without indiviual tolerance indications.

According to ISO2768-1:1989, Values in millimeters.

Basic size range |

F(Fine) |

M(Medium) |

C (Coarse) |

V(Very coarse) |

|---|---|---|---|---|

|

0.5 up to 3 |

±0.05 |

±0.1 |

±0.2 |

- |

|

over 3 up to 6 |

±0.05 |

±0.1 |

±0.3 |

±0.5 |

|

over 6 up to 30 |

±0.1 |

±0.2 |

±0.5 |

±1.0 |

|

over 30 up to 120 |

±0.15 |

±0.3 |

±0.8 |

±1.5 |

|

over 120 up to 400 |

±0.2 |

±0.5 |

±1.2 |

±2.5 |

|

over 400 up to 1000 |

±0.3 |

±0.8 |

±2.0 |

±4.0 |

|

over 1000 up to 2000 |

±0.5 |

±1.2 |

±3.0 |

±6.0 |

|

over 2000 up to 4000 |

- |

±2.0 |

±4.0 |

±8.0 |

Why Choose Us to Make Your Machined Parts

- Fully Equipped CNC Machine Shops

Our in-house facilities are built for precision. Nakamura-Tome, Okuma, Mazak, Mikron, DMG Mori, Tsugami, Gleason, and more. You get exactly what you ordered, correct materials, tight tolerances, and consistent quality.

- Instant Quotes With Real Engineering Support

Upload your 3D CAD files and receive a quote within 24 hours. Our senior engineers review each design to catch potential issues early thin walls, deep cavities, tricky threads, or tolerance risks and provide practical, manufacturable suggestions that save you time and cost.

- End-to-End Quality Assurance

From First Article Inspection (FAI) to CMM reports and full Material Test Reports (MTR), every CNC part goes through a strict quality workflow. Surface finish, dimensions, and tolerances are verified before shipment, ensuring you receive parts that perform exactly as intended.

Order Processing

Upload Your Design

Upload Your Design

Upload your CAD or 3D files along with specifications, tolerances, and any notes needed to ensure accurate machining.

DFM Review & Quote

DFM Review & Quote

Our engineering team evaluates manufacturability, offers improvement suggestions, and sends a quote with lead time, typically within 24 hours.

Production & Quality Control

Production & Quality Control

After your approval, parts are manufactured under ISO 9001:2015 standards with both in-process and final inspections. Inspection reports are available upon request.

Worldwide Shipping

Worldwide Shipping

Once completed, your parts are securely packaged and shipped to customers worldwide. Ensuring safe, on-time delivery with full tracking visibility.

#Contact Us

Custom CNC Machined Part With Easy

Upload your design files for quote pricing, free DFM analysis.

Email: sales@yp-mfg.com

Whatsapp / Phone: (86) 137 9493 0097

Request a Quote Now!

Send drawings and detailed requirements via

Or fill out the contact form below:

- All files are secure and confidential.

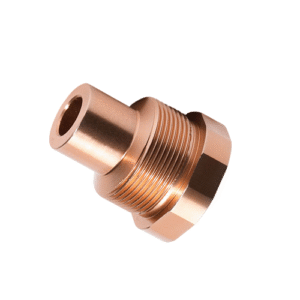

YP-MFG CNC Machining Materials

Over 300+ Material Options – high-performance materials, including metal ( aluminum, copper, stainless steel, steel, bronze, titanium) and plastics (PEEK, ABS, PC), and advanced composites.

Aluminum properties: Flexible and ductile, easy to make alloys, high strength-to-weight ratio, excellent corrosion resistance, easy to conduct electricity and heat, and recyclable.

Alloys: 6061-T6, 7075-T6, 2024, 5052, 6060, 5083, 2017, 6082

Applications: Aerospace components, automotive parts, electronic product housings, building structures, etc.

Stainless Steel Properties: health care, corrosion resistance, fine surface treatment, high rigidity, can be formed by various processing techniques, difficult to cold process.

Subtypes: Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

Applications: Austenitic stainless steel is mainly used in household goods, industrial pipes and building structures. Martensitic stainless steel is mainly used to make knives and turbine blades. Ferritic stainless steel has corrosion resistance and is mainly used in durable washing machines and boiler parts. Composite stainless steel has stronger corrosion resistance, so it is often used in corrosive environments.

Steel Properties: Steel is a strong, durable, and versatile material with excellent machinability, weldability, and the ability to be heat-treated for enhanced performance.

Subtypes: Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

Applications:Chassis, body panels, engine parts, gears, shafts, bearings, machine frames, couplers, and load-bearing structures,Cutting tools, hand tools, fasteners, and protective casings.

Brass Properties: An alloy of copper and zinc. When the zinc content is less than 39%, zinc can dissolve in copper to form a single phase a, called single-phase brass, which has good plasticity and is suitable for hot and cold pressure processing. When the zinc content is greater than 39%, there is a single phase a and a copper-zinc-based solid solution b, called dual-phase brass. b reduces plasticity and increases tensile strength, and is only suitable for hot pressure processing.

Alloy: C360, C260

Applications: Widely used in structural parts of electrical appliances, such as bolts, nuts, washers, springs, etc.

Copper properties: Very good corrosion resistance, excellent thermal and electrical conductivity, hard, flexible, ductile, and has unique effects after polishing.

Grade: C10100, C11000, C12200, C14500, C17200

Applications: Wires, motor coils, printed circuits, roofing materials, electrical connectors, instrumentation

Titanium: Very high strength, good corrosion resistance to weight ratio, difficult to cold work, good weldability, about 40% lighter than steel, 60% heavier than aluminum, low conductivity, low thermal expansion, high melting point.

Titanium Alloy: TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

Applications: Golf clubs, tennis rackets, laptops, cameras, luggage, surgical implants, aircraft frames, chemical tools, and maritime equipment.

Bronze Properties: Bronze generally has good corrosion resistance, wear resistance, castability and excellent mechanical properties.

Subtype: Tin Bronze

Applications: Suitable for casting various utensils, mechanical parts, bearings, gears, etc.

ABS: Composed of three monomers: acrylonitrile (A), butadiene (B), and styrene (S). It is a common plastic with high mechanical strength and good comprehensive performance. The outstanding feature is that the surface can be electroplated and painted. ABS is easy to absorb moisture, has stable dimensions, and is easy to shape and process.

Types: ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White

Applications: It is widely used in the manufacturing industry and chemical industry, such as parts and shells in the automotive, electronic appliances, toys, construction and other industries.

PC Properties: It is the best impact-resistant plastic variety with good mechanical properties, dimensional stability, acid and alkali resistance, and water absorption. It has high mechanical, optical, electrical and thermal properties.

Types:

PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black

Applications: household appliances, automotive lamps, medical instruments, packaging containers, and small load, low speed wear-resistant parts such as gears, worms, bushings, etc.

PEEK Properties: Resistant to chemical corrosion, flame retardant, wear resistant, radiation resistant, not resistant to strong nitric acid and concentrated sulfuric acid, with super strong mechanical properties

Grade: Unfilled PEEK, 30% glass-fiber reinforced PEEK, 30% carbon-fiber-reinforced PEEK, Bearing Grade PEEK

Applications: various mechanical parts, such as automobile gears, oil screens, shift starter discs, aircraft engine parts, etc.

PMMA (Acrylic): Applicable to -40 to 90℃ range, UV resistance, good weathering resistance, resistance to inorganic acids and alkalis, lipid hydrocarbons and detergents, tear resistance is better than other plastics. It has good electrical and dielectric properties and excellent mechanical strength.

Grade: Extruded PMMA, Cast PMMA, Impact-Modified PMMA, UV-Stabilized PMMA, Heat-Resistant PMMA

Applications: Machine covers and accessories, clock scale plates, electric fan blades, relay covers, windshields, electrical medical equipment, transparent models, specimens, decorations, dentures, advertising nameplates, etc.

CNC Machining Finishes Service

YP-MFG CNC Machining Finishes Service offers a wide range of surface treatments, including anodizing, powder coating, polishing, plating, sandblasting, and more. Get precision-finished parts tailored to your design and performance needs.

As Machined

Ideal for functional prototypes or internal components where appearance is not critical, this finish provides the shortest lead time and maintains tight tolerances without additional processing.

Anodizing

Anodizing is an ideal choice for forming a corrosion-resistant coating on processed aluminum and titanium parts.

Heat Treatment

Polishing

Electroplating

Typical products: Surface treatment of transportation, consumer electronics, furniture, jewelry and silverware, etc.

Powder Coating

Typical products: spraying of transportation, construction and white household appliances, etc.

Suitable production: single piece to large batch.

Quality: product surface coloring is smooth and uniform.

Sand Blasting

Painting

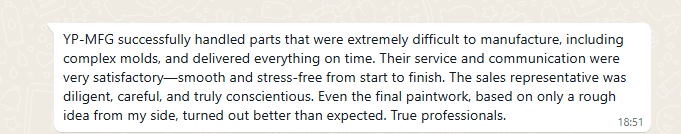

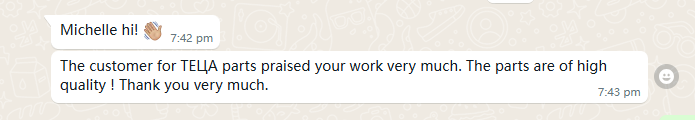

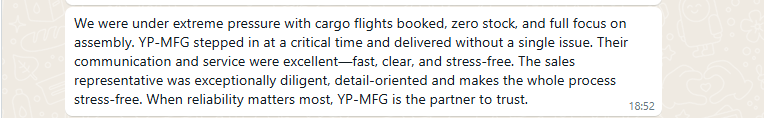

See What Our Customers Say About Us

5/5★ Rated: See Why 2000+ Clients Trust Our CNC Machining Service

CNC Machining FAQs

In the aerospace industry, it is used to manufacture engine parts, turbine blades, and structural components. The automotive sector relies on CNC machining for producing engine blocks, transmission housings, and custom parts. In the medical field, it enables the production of surgical instruments, prosthetics, and implants with strict tolerance and material requirements. The electronics industry uses CNC machining for making heat sinks, connectors, and enclosures. Additionally, industrial equipment manufacturing, consumer products like eyewear and furniture, robotics and automation systems.

YP-MFG is known as one of the best CNC machining companies in China in terms of quality, speed, and customer service. CNC milling generally maintains ±0.01–0.003 mm, CNC turning achieves ±0.005–0.025 mm, and Swiss-style turning can reach ultra-precision levels of ±0.003 mm. Processes like EDM and grinding can further improve accuracy, achieving tolerances down to ±0.001 mm.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

CNC machining prices vary depending on factors such as material, part complexity, tolerances, quantity, and lead time. For prototyping or small batches, costs usually range from $75 to $150 per hour of machine time, or around $50 to $200 per part. In medium to large-scale production, the per-part cost can drop significantly, sometimes to as low as $5 to $50 depending on volume and design simplicity. If needed, YP-MFG can assist in preparing a quote request based on your specific needs.

The sample of your own design needs to pay for the mold set up charge. Samples production takes 5-7 working days after set up charge received & size drawing approval.

Sure, we will not display any customers' design or show to other people, we can sign NDA.

Yes, We can work overtime and add a few machines to produce these products if you need it urgently.

Start Your CNC machining Project Today

Discover the benefits of custom parts designed by experts. From small-batch prototypes through large-scale manufacturing, we deliver custom answers to make your wishes come true.