# Cnc Machining On-Demand Production for

New Energy

- Tolerances up to +/- 0.003 mm

- Engineering Support, High Quality

- ISO 9001:2015 Certified

- Fast Lead Time

Get an Instant Quote Now

- Upload Your Project Files

- Get Instant Quote

- High-Precision Parts in Hand!

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All files are secure and confidential.

Reliable Machined Parts for New Energy Industry

YP-MFG is a one-stop machining shop that provides a full range of services from custom machinery manufacturing, five-axis machining, turning and milling services. Whether it is precision components for solar panels, turbine components for wind power generation, or specialized components for natural gas energy systems, our advanced CNC machine tools ensure that each product has excellent quality and precision. Our commitment to precision, safety and quality has made us a leader in machining for the energy industry.

- ISO certified

- Skilled and experienced

- Huge production capacity

- Competitive pricing

- Material Versatility

- High quality, functionality products

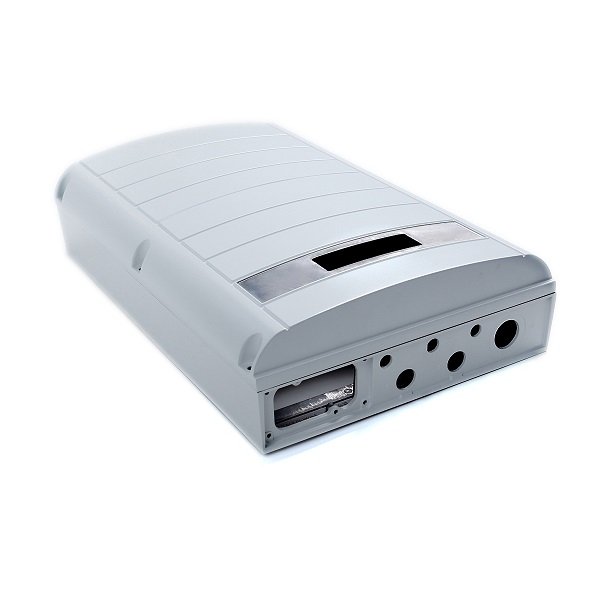

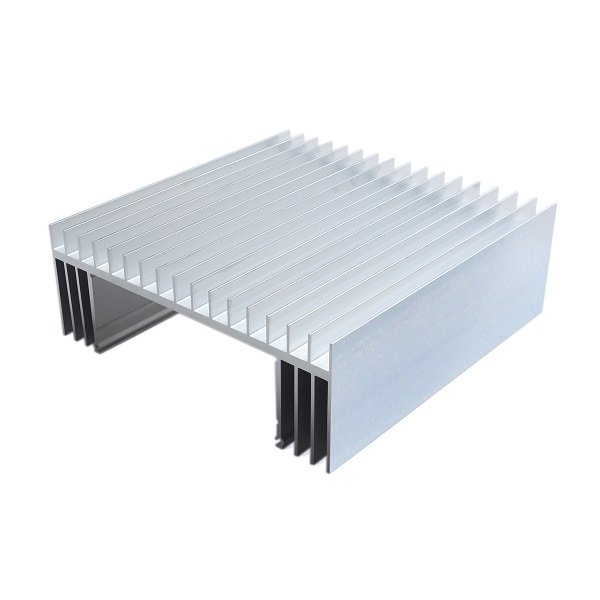

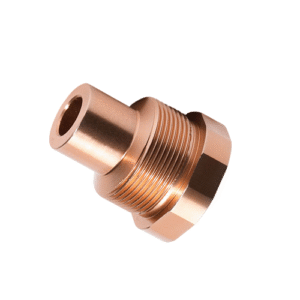

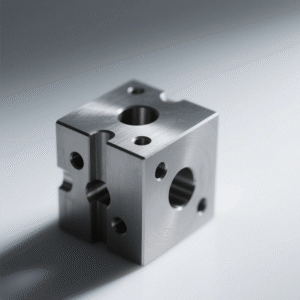

Engery Parts We Made

From solar panel components to wind turbine parts, valves, houshing,and more. For those in the energy industry seeking a trusted partner for custom machining services, YP-MFG offers the expertise, technology, and dedication needed to move your projects forward.

New Energy Machining Products Applications

- Solar panel parts

- Housings

- Heat exchangers

- Fasteners & Connectors

- Generator components

- Turbine components

- Impellers

- Casings

- Rotors

- Bushings

- Jigs and Fixtures

- Composite tooling

- Hydraulic Components

- Critical Components

- Battery components

- Ducts and ventilation

our services

Custom New Energy Machining Solutions

New Energy Manufacturing Materials

We offer a vast selection of high-performance materials for the new energy industry. Upload your project to us – we are ready to collaborate and bring your parts for you.

Aluminum properties: Flexible and ductile, easy to make alloys, high strength-to-weight ratio, excellent corrosion resistance, easy to conduct electricity and heat, and recyclable.

Alloys: 6061-T6, 7075-T6, 2024, 5052, 6060, 5083, 2017, 6082

Applications: Aerospace components, automotive parts, electronic product housings, building structures, etc.

Stainless Steel Properties: health care, corrosion resistance, fine surface treatment, high rigidity, can be formed by various processing techniques, difficult to cold process.

Subtypes: Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

Applications: Austenitic stainless steel is mainly used in household goods, industrial pipes and building structures. Martensitic stainless steel is mainly used to make knives and turbine blades. Ferritic stainless steel has corrosion resistance and is mainly used in durable washing machines and boiler parts. Composite stainless steel has stronger corrosion resistance, so it is often used in corrosive environments.

Steel Properties: Steel is a strong, durable, and versatile material with excellent machinability, weldability, and the ability to be heat-treated for enhanced performance.

Subtypes: Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

Applications:Chassis, body panels, engine parts, gears, shafts, bearings, machine frames, couplers, and load-bearing structures,Cutting tools, hand tools, fasteners, and protective casings.

Brass Properties: An alloy of copper and zinc. When the zinc content is less than 39%, zinc can dissolve in copper to form a single phase a, called single-phase brass, which has good plasticity and is suitable for hot and cold pressure processing. When the zinc content is greater than 39%, there is a single phase a and a copper-zinc-based solid solution b, called dual-phase brass. b reduces plasticity and increases tensile strength, and is only suitable for hot pressure processing.

Alloy: C360, C260

Applications: Widely used in structural parts of electrical appliances, such as bolts, nuts, washers, springs, etc.

Copper properties: Very good corrosion resistance, excellent thermal and electrical conductivity, hard, flexible, ductile, and has unique effects after polishing.

Grade: C10100, C11000, C12200, C14500, C17200

Applications: Wires, motor coils, printed circuits, roofing materials, electrical connectors, instrumentation

Bronze Properties: Bronze generally has good corrosion resistance, wear resistance, castability and excellent mechanical properties.

Subtype: Tin Bronze

Applications: Suitable for casting various utensils, mechanical parts, bearings, gears, etc.

Titanium: Very high strength, good corrosion resistance to weight ratio, difficult to cold work, good weldability, about 40% lighter than steel, 60% heavier than aluminum, low conductivity, low thermal expansion, high melting point.

Titanium Alloy: TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

Applications: Golf clubs, tennis rackets, laptops, cameras, luggage, surgical implants, aircraft frames, chemical tools, and maritime equipment.

PC Properties: It is the best impact-resistant plastic variety with good mechanical properties, dimensional stability, acid and alkali resistance, and water absorption. It has high mechanical, optical, electrical and thermal properties.

Types:

PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black

Applications: household appliances, automotive lamps, medical instruments, packaging containers, and small load, low speed wear-resistant parts such as gears, worms, bushings, etc.

ABS: Composed of three monomers: acrylonitrile (A), butadiene (B), and styrene (S). It is a common plastic with high mechanical strength and good comprehensive performance. The outstanding feature is that the surface can be electroplated and painted. ABS is easy to absorb moisture, has stable dimensions, and is easy to shape and process.

Types: ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White

Applications: It is widely used in the manufacturing industry and chemical industry, such as parts and shells in the automotive, electronic appliances, toys, construction and other industries.

PEEK Properties: Resistant to chemical corrosion, flame retardant, wear resistant, radiation resistant, not resistant to strong nitric acid and concentrated sulfuric acid, with super strong mechanical properties

Grade: Unfilled PEEK, 30% glass-fiber reinforced PEEK, 30% carbon-fiber-reinforced PEEK, Bearing Grade PEEK

Applications: various mechanical parts, such as automobile gears, oil screens, shift starter discs, aircraft engine parts, etc.

New Energy FAQs

Produces parts for EVs, solar, wind, and hydrogen systems

Enables lightweight, efficient components that reduce energy use

Supports just-in-time production, reducing waste

Yes. Relevant certifications may include:

ISO 9001 (quality management)

IATF 16949 (automotive quality – EV industry)

AS9100 (aerospace-related clean energy)

ISO 14001 (environmental management)

Produces parts for EVs, solar, wind, and hydrogen systems

Enables lightweight, efficient components that reduce energy use

Supports just-in-time production, reducing waste

Tight tolerances for thermal and electrical performance

Material sourcing (e.g., copper, titanium)

High mix/low volume production in emerging technologies

Continuous updates with evolving energy standards

We understand the importance of verifying quality and compatibility before full production. You can request a prototype or sample part to evaluate our machining quality, material selection, and tolerances before committing to a larger order.

#Contact Us

Custom New Energy Machined Part With Easy

Upload your design files for quote pricing, free DFM analysis.

Email: sales@yp-mfg.com

Whatsapp: + 86 137 9493 0097

- Quote Check List:

- 3D and 2D files if available

- Quantity of each part

- Material and grade

- Surface finish if necessary

Request a quote Now!

- All files are secure and confidential.