By Phileas Reid | Tuesday, February 2Are you the type of person who enjoys peeling back all those layers so that no one knows how something is cooked? Well gearheads, This one probably tickle your gearbox - Say Hello to the aluminum machining world! Machining is a process of transforming raw materials onto finished products in any field using machines such as lathe, milling etc. In this article, we will look at how to machine 6061 aluminum - a material used in the fabrication of parts for aerospace components along with automotive and electronic devices. Your guide to everything you need to know before stepping into cold water and start exploring the world of machining this amazing material - from a myriad tricks & tips, through knowledge needed for setting out.

An issue that may come across through cutting 6061 aluminum is it's harder to hold tight tolerances, posing the ultimate question of how much you can really get away within your design. When working with this material then as well to be at a high level in precision, no ends are too far away simply for details done correct and use whatever equipment is possible. Since you can repeat machining operations with exact precision by using CNC (computer numerical control) machines, the most stricted tolerances are easier to achieve. Not to forget, proper holding fixtures/workholding devices aid in dependable material positioning and clamping which is crucial as it considerably contributes towards a tighter tolerance being maintained.

Machining is not only manufacturing but it sparks innovation by offering the ability to think of new ideas about what will work and look good, you have been able to develop this through-out your career in terms of materials/methods being involved. This is a 6061 Aluminium machined model of your versatility that can be utilised to do the production-ready prototyping, then later you could yield optimize when needed. Great way to see how what you are doing has a potential affect.. try different maching strategiues or methods and SEE it show in the finished product. This progressive method opens the door to creative experimentation in machining, which nurtures growth of their metalworking craft.

When cutting 6061 aluminum, it is essential to use the right tools and methods if you want success. For cutting tools, choosing proper geometries or coatings can double tool life and significantly increase the quality of machined parts. In addition, using the right feeds and speeds (the rate at which a tool moves through material) would make it possible to hit an effective surface finish. How the coolant/lubricant is chosen with respect to material and cutting characteristics will also greatly affect tool life. Machine work is a learning process, it takes thought study and the use of different tools (real machine tools) to better manipulate your task in ways that result in credible (better) products.

Consequently, machining 6061 aluminum is a remarkable and also fulfilling procedure that takes exceptional accuracy as well as workmanship with the ideal devices along with strategies. These tips and tricks will push the tightest tolerances you need to make a quantitative part, can leverage entire new manufacturing of all kinds while underlying your work more efficiently able to understand something about tool or approach so well that if it is correct for the job. No matter if you are a young (for the most part) engineer that seeks to learn and expand on their hands-on experience with machining, or an experienced seasoned one familiarized by way too CAD/CAM methods - 6061 aluminum machining surrounding world is promising interesting exploration of plenty more manufacturing subtleties involved overall -- now get busy milling some badass parts!

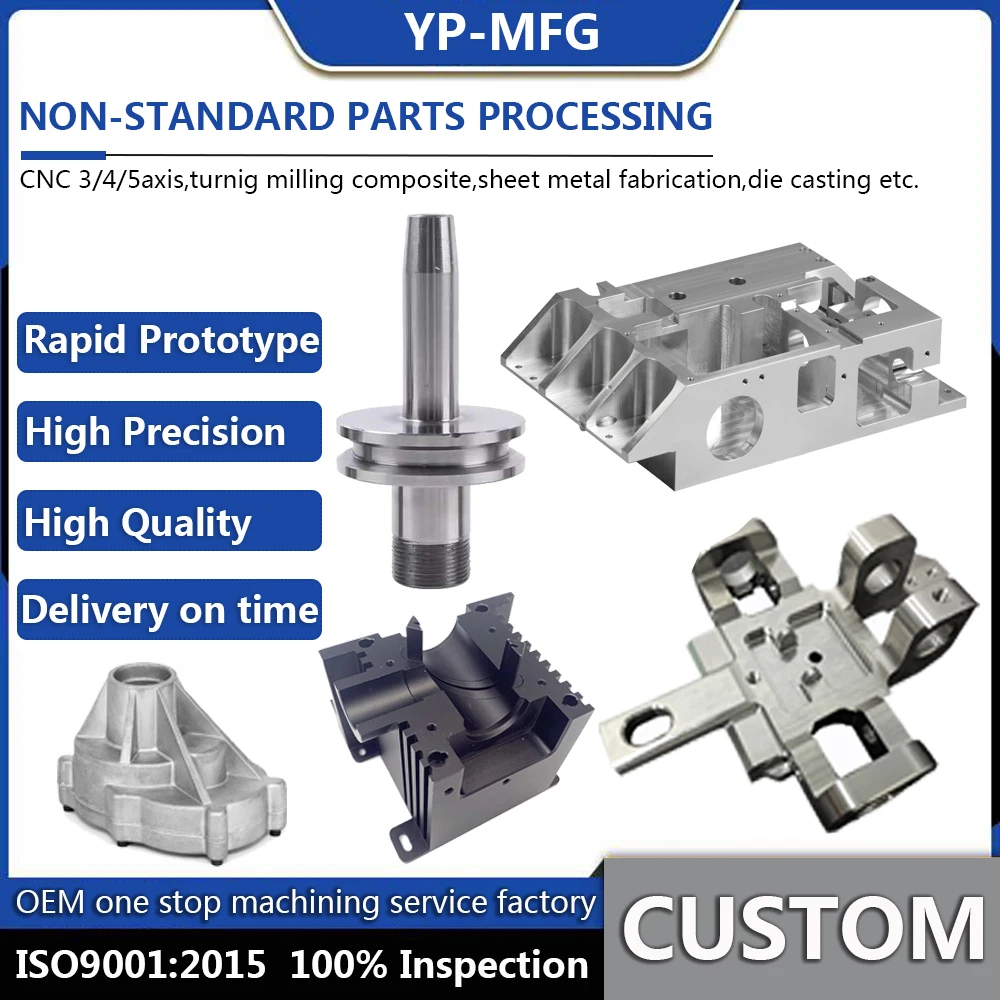

YP MFG is a strict adherent to ISO 9001:2015 standards for 6061 aluminum machining processing.The dimensions are tested both prior to and following surface treatment.Tolerence standards are generally the ISO 2768-F standard is ours. can also accommodate drawings that meet specific requirements.

YP-MFG offers wide range CNC cutting.service include CNC 6061 aluminum machining, CNC turning, stamping, laser die-casting, forging, all kind surface treatment, assembly and so on.

YP MFG home more than 70 latest machines ensure quality speed delivery.machines include Milron from Swiss, Brother from Japan, Jingdiao from China and more.We have 15 sets of 5 axis machines, 39 sets of 4 machines with axes and 3 Axis machines. We also have 16 sets of 6061 aluminum machining machines.

YP-MFG has been in 6061 aluminum machining manufacturing for more than 20 years. Our engineers are knowledgeable.Our customer are from allover the world, EU, US, AU, Asian.More than 90 percent of our items exported all over the world.In the 20 years we have been in business, we understand different request and culture from different regions and the different requests that used at different locations.